Hydrogen cylinder

- size :

Φ138mm*680MM

- thickness:

5mm

- material:

stainless steel 304

- application:

Oxygen tank

Application

Carbon fiber hydrogen cylinders, it is also called hydrogen tank. as high-performance energy storage devices, are gradually becoming an important choice in multiple fields. So, what exactly are the uses of carbon fiber hydrogen cylinders?

1. Energy storage and transportation

● Hydrogen energy storage

With the enhancement of environmental awareness and the development of renewable energy, hydrogen, as a clean and efficient form of energy, has received increasing attention. Carbon fiber hydrogen cylinders have become an good choice for hydrogen storage due to their light weight, high strength and good corrosion resistance. it can withstand high pressure, ensuring the safe storage of hydrogen, the entire hydrogen storage system becomes more efficient.

● Hydrogen energy transportation

Besides storage, carbon fiber hydrogen cylinders are also widely used in the transportation process of hydrogen. Safe and reliable storage containers are of vital importance in the process of transporting hydrogen from the production site to the usage site. Carbon fiber hydrogen cylinders not only provide the necessary strength and stability, but also reduce the weight burden during transportation, thereby lowering energy consumption and transportation costs.

2. Aerospace field

The aerospace field has extremely high requirements for the weight and performance of equipment. Carbon fiber hydrogen cylinders have demonstrated remarkable advantages in this field.

● Propulsion system fuel storage

In spacecraft, the performance of the fuel storage system directly affects the overall performance and mission execution capability of the spacecraft. Carbon fiber hydrogen cylinders, as lightweight and high-strength storage containers, can effectively reduce the weight of spacecraft, enhance their payload capacity and flight performance.

● Life safety systems

In the aerospace field, carbon fiber hydrogen cylinders are also frequently used in life safety guarantee systems. For instance, in an emergency, spacecraft may need to use stored hydrogen to provide astronauts with breathing gas or for other emergency escape measures. The reliability and stability of carbon fiber hydrogen cylinders are particularly important in this situation.

3. The Automotive Industry

With the continuous development of hydrogen fuel cell technology, the demand for carbon fiber hydrogen cylinders in the automotive industry is also increasing.

● Hydrogen fuel cell vehicles

Hydrogen fuel cell vehicles are an important part of sustainable transportation in the future. These cars use hydrogen as fuel and generate electricity through fuel cells to drive the vehicles. Carbon fiber hydrogen cylinders offer a safe and efficient hydrogen storage solution for this type of vehicle, making the commercial application of hydrogen fuel cell vehicles possible.

● Enhance driving range and safety

The lightweight feature of carbon fiber hydrogen cylinders helps to improve the driving range of vehicles. Meanwhile, its high strength and corrosion resistance can also ensure the safety of the car during driving. Even under extreme conditions, carbon fiber hydrogen cylinders can maintain stable performance, providing reliable safety guarantees for passengers.

To sum up, carbon fiber hydrogen cylinders have extensive applications in fields such as energy storage and transportation, aerospace, and the automotive industry. With the continuous advancement of technology and the increase in market demand, carbon fiber hydrogen cylinders are expected to play a greater role in the future and contribute to promoting sustainable development and the clean energy revolution.

Spin forming technology

Seamless gas cylinder inner liner is manufactured through metal spinning process (such as aluminum alloy), combined with fiber winding (carbon fiber/glass fiber) reinforced structure to achieve lightweight and high pressure-bearing capacity (working pressure up to 35-70 mpa).

Technical advantage

● Lightweight

Type IV bottle (plastic inner liner + carbon fiber winding) has a weight-to-volume ratio as low as 0.25-0.35kg/L, suitable for mobile applications

● Safety

Enhanced blast resistance through fiber ring winding, suitable for ambient temperatures ranging from -40 ° C to 60 ° C. The current spinning process is driving hydrogen storage cylinders towards higher pressure (such as 100MPa) and lower cost.

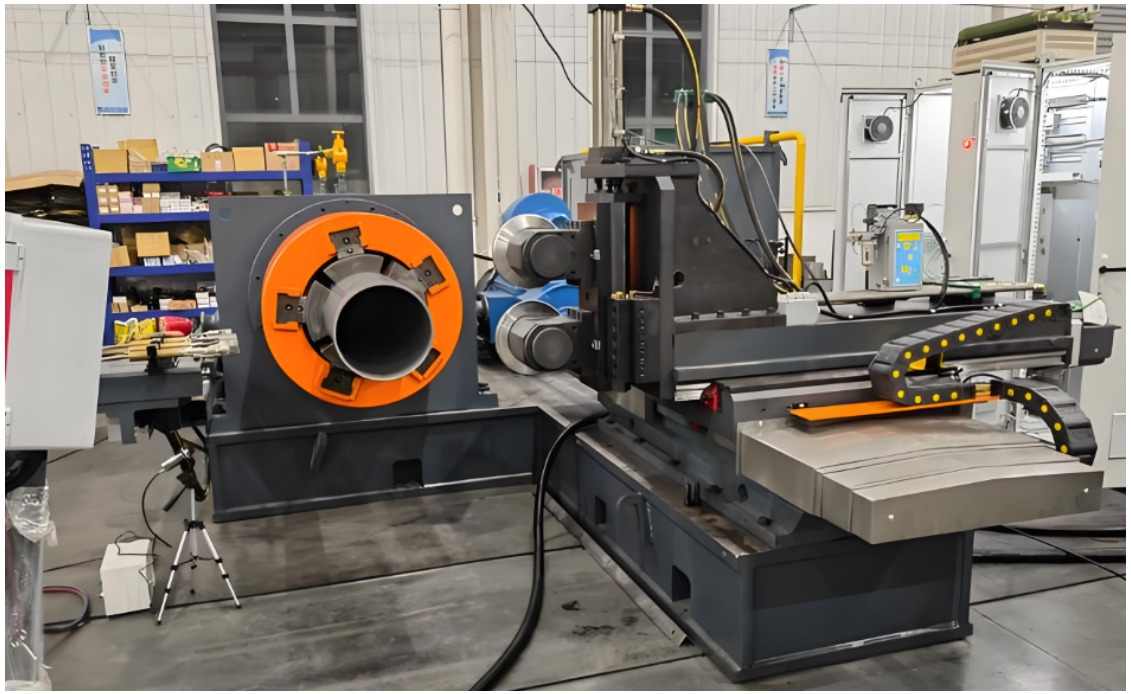

Hydrogen cylinder spinning machine

The hydrogen cylinder spinning machine is a specialized tube spinning forming equipment. Different from the traditional plate spinning equipment, the hydrogen cylinder spinning machine does not have a tailstock. Since the raw materials of hydrogen cylinders are all tube materials, the main shafts of hydrogen cylinders are relatively large and are equipped with a dedicated tube spinning fixture. The raw materials of hydrogen cylinders are all 6061 aluminum, which has both excellent hardness and tensile strength During the forming process of hydrogen cylinders, the blanks need to be heated appropriately. Therefore, the hydrogen cylinder spinning machine can be simply understood as a large-sized tube spinning machine with heating.

The manufacturing ways

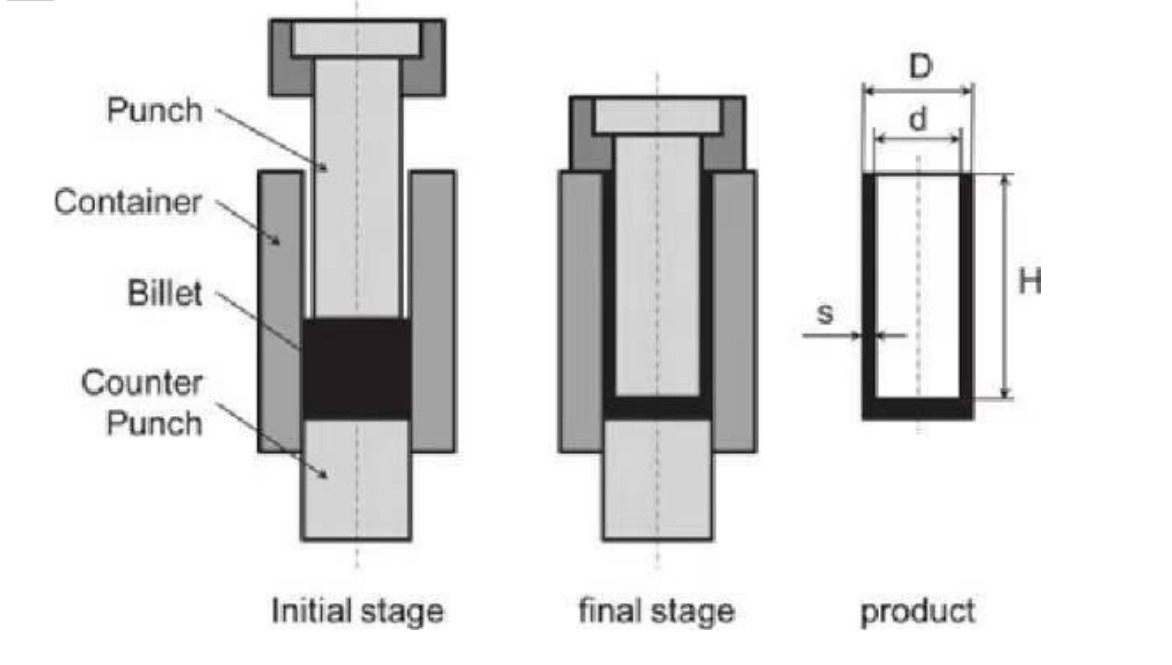

1. Aluminum reverse extrusion ( small size )

Aluminum reverse extrusion, also known as indirect extrusion or backward extrusion, is a metal forming process where the aluminum billet is stationary while the die moves toward it, forcing the metal to flow in the opposite direction of the applied force.

The reverse extrusion process of aluminum is mostly used for the production of small hydrogen cylinder blanks. This processing technology has a very high production efficiency, often reaching 1,000 to 4,000 units in a day. The thicker the wall thickness and the longer the length of the hydrogen cylinder, the larger the model used. Most of the models on the market can generally produce up to 400mm in height. However, for aluminum reverse extrusion processing, the height exceeds 600mm, and there are very few machines available on the market. However, in the production of hydrogen cylinders, the general length exceeds 300mm.

2. Flow forming ( large size )

Large hydrogen cylinder rough blanks need to be subjected to strong spinning and stretching of aluminum forging rough blanks by a three-wheel spinning machine. After being extruded by a three-wheel strong spinning machine, the wall thickness of the aluminum blank becomes thinner, the length becomes longer, and the precision can be controlled at 0.1mm, greatly enhancing the tensile strength.

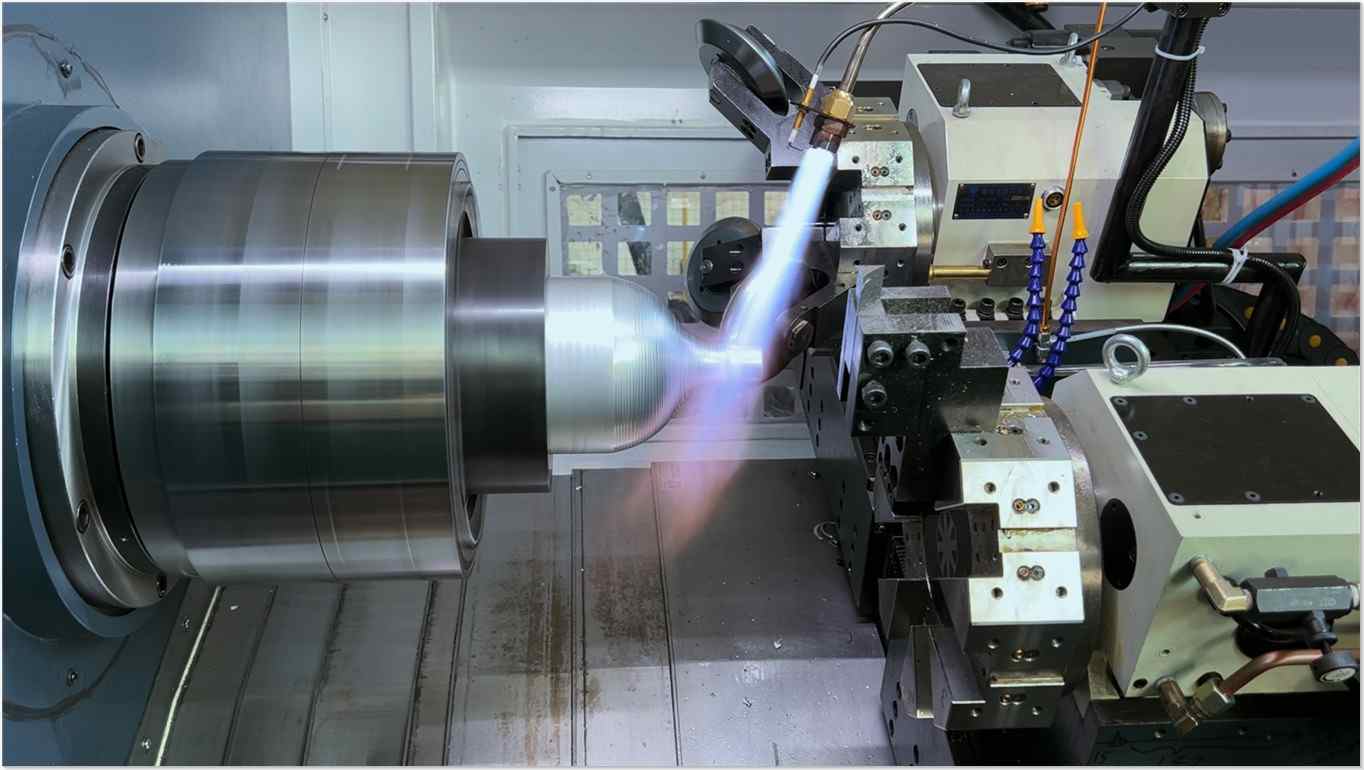

3. Necking Spinning

The rough blanks made by reverse extrusion or three-wheel manufacturing of aluminum are placed on a dedicated hydrogen cylinder tube spinning equipment for spinning and compressing. During this process, the blank tubes need to be heated to enhance the fluidity of the material, and the wall thickness of the blank will increase.

4. CNC boring

After the nozzle of the hydrogen cylinder is helically compressed, a threaded hole is usually made by CNC boring to install and seal.

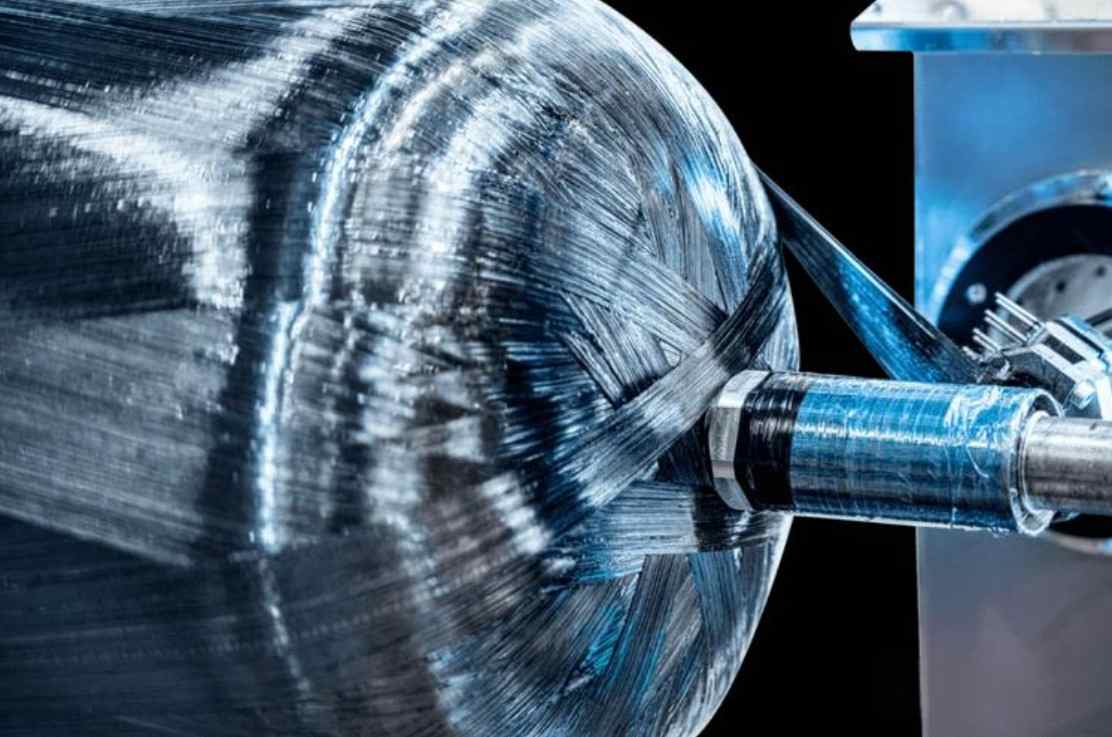

5. Carbon fiber

The density of carbon fiber is only 1.5 to 2.0 g/cm³ (approximately one fourth of that of steel), but its tensile strength can reach 7 to 9 times that of steel (≥ 350 MPa). This characteristic enables the hydrogen storage tank to withstand a pressure of 70 MPa (equivalent to 700 kilograms per square centimeter of pressure), while significantly reducing the overall weight and improving the range efficiency of hydrogen fuel cell vehicles. For instance, the IV type bottle adopts a fully carbon-fiber wrapped structure, and the hydrogen storage mass ratio can reach 6% to 7%.