Metal spinning is a metal working process that can make a metal disc or sheet deform different shape of revolving body in a lathe or machine. The mold (it is also called mandrel) and clamp provide the clamping force and take the sheet to spin. When the spinning roller touch and press the sheet according to the spinning path, the sheet will produce plastic deformation from the point to the line follow the spinning roller.

Spin forming

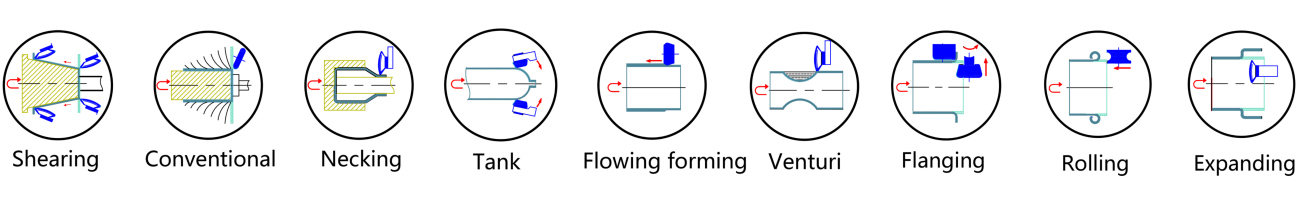

Spin forming technology, tolerance, performance are related to many process parameters and factors, such as the accuracy of CNC spinning machine, mold design, spinning path, roller radius, spindle speed, feed speed, spinning temperature, thinning rate. At same times, the tensile strength, hardness, ductility, spring back of blank materials decides the difficulty of spin forming. The spinning processing method is flexible and changeable, you can choose conventional, shearing, necking, flanging, hemming, flow forming according to the structure and characteristics of different spun products. Welcome to Dinnovation, Let us take you go to the world of spin forming technology.

Dinnovation metal spinning is located in China, Factory building covers an area of 1800 square meters. We invest 8 CNC spinning machines and other fabrication machines such as rolling, deep drawing, flanging, welding, 5 axis laser cutting. There are 16 members in our team, we continually try and test the different material and fabrication ways to promote the development of metal forming technique. Advanced machines and excellent resources support your phases. We successfully supply the venturi, funnel, fireplace, firebowl, container, tank, turbine, turbojet, burner nozzle, Combustion chamber, combuster, signal reflecter, military and aerospace components in the market, the export value of metal spun parts are more than 200,000 pieces every year.

Application

Metal spun products have good tensile strength and hardness after pressing and shearing, it is widely used in the manufacturing. Now Dinnovation supplies more than 200 types of industries, we are expert in precision metal spin forming, to give the appropriate advice to finish your project, it greatly saves customer's time and mold cost. Our metal spun product Max diameter is 1300mm, Max Heigh is 800mm, Max thickness 15mm, Min tolerance is 0.2mm.

In addition to aluminum, copper, brass, iron, stainless steel sheet spinning, Dinnovation has achieved good applications in the hot spinning of special material such as Superalloy (high-performance alloy), Inconel 718 and 625 (nickel-basedf superalloys), Hardox (high wear-resistance), aerospace grade Aluminum 2024 and 7075, these metal have high tensile strength and hardness. From 2019, Dinnovation has a big breakthrough in tube spinning, we have spun 8-14 inches of stainless steel venturi valve, the aluminum 6061 oxygen and hydrogen tank.

Advantage and solution

Spun metal parts

The major country : America, German, Israel, Korea, Malaysia, Portugal, UK, France, Spain, Ireland, Turkey, Japan, Netherlands, Italy, Canada, New Zealand, India, Vietnam.

Industries : 200 kinds of insdustries in total.

The fabrication : spun metal, deep drawing, CNC, stamping, 5-axis laser cutting and welding, CNC milling and turning.

Precision industries

Aircraft : Turbine Turbojet Tailpipe Tail-jet Fairing Nozzle

Aerospace : Combustion chamber Oxygen-tank Nozzle

Military parts : Liner Reflector Radar

Services