What is metal spinning | spin forming

Metal spinning is a metal working process that can make a metal disc or sheet deform different shape of revolving body in a lathe or machine. The mold (it is also called mandrel) and clamp provide the clamping force and take the sheet to spin. When the spinning roller touch and press the sheet according to the spinning path, the sheet will produce plastic deformation from the point to the line follow the spinning roller.

Advantage >>

1. Cheaper mold and material

Metal spinning is a necessary metal forming ways in the manufacturing, Compare to other metal forming ways such as hydraulic forming and water expansion, the metal spinning mold (mandrel) is cheaper and simpler, compare other machining process such as CNC turning, it form a circular metal sheet into various shapes without removing materials from the workpiece,the materials cost is the cheaper.

2. Higher tensile strength and hardness

Most of all, metal spun products have better tensile strength, hardness, tolerance after pressing and shearing by spinning roller, it can be endured the worst working environment. A famous Japanese company have been tested the same thickness, material and shape of part that is respectively made by metal spinning, deep drawing, CNC Turing. When put these parts in a specified working environment that endured the torque and high temperature, the deep drawing and CNC turning part will can't work after losing 60 percent of of the original accuracy and tensile strength after 8 hours, but the metal spinning products just lost 10 percent of its accuracy and tensile strength, it still can work availably. This is why the aerospace and special equipment industries choose the metal spinning to process the part.

Working principle

1. Spin forming principle

Spindle take and clamp sheet or tube to turn, the roller pull and press the sheet or tube to form different shape according to the roller path. It is similar with the handmade ceramic craft, the function of spinning roller is equivalent to the hands of making ceramic.

2. Spinning deformation force

● Clamping force of tailstock : outputed by air pressure or hydraulic cylinder of tailstock, the friction force of clamp can make the sheet turn follow the spindle.

● Turning force of spindle : outputed by spinndle motor and take metal sheet to turn.

● Pressing and pulling force of roller : outputed by X-axis and Z-axis motor, when roller touch the workpiece, the touching point will pulled and pressed by roller according to the spinning path.

3. Axial and radial deformation

● Axial deformation : Axial of metal sheet will be longer and thinner after pulling of spin roller.

● Radial deformation : Radial of metal sheet will be smaller after pressing of spin roller, the spinning roller move path is a helical line.

Development >>

1. Hand spinning

Hand spinning is an ancient craft, it is also called manual spinning. Europe began to use hand spinning to make some metal crafts in the 18th century, it is limited by the force of metal spinner, it can’t form the thick and hard metal. The common hand spinning materials are aluminum, copper, brass and steel, these metal are soft and the ductility is good compare to other metal. Hand spinning is used in the tableware, lamp shadow, vase, many metal spinning products are popular in European homes and hotels.

2. CNC metal spinning

CNC metal spinning develop and research based on hand spinning, Hand spinning control spinning roller to move by hand, CNC metal spinning control the spinning roller to move by CNC (computer numerical control ).

It's different from hand spinning, CNC metal spinning can output stronger spinning force to form the thicker and harder metal, the blank sheet or tube has not only conventional deformation but also shearing deformation, shearing deformation can make the grain refine, the tensile strength and hardness are improved greatly. At the same time, the accuracy of CNC metal spinning is higher than hand spinning.

The difference between hand spinning and CNC metal spinning>

Materials >>

Main bank metal classify tube and sheet, the other blank shell made by Deep drawing and casting can be used in metal spinning as well. Metal spinning is divided into tube spinning and sheet spinning according to the blank metal tube and sheet.

1.Material shape

2.Sheet performance

Sheet is classified cold rolling sheet and hot rolling sheet. The hardness and tensile strength of cold rolling sheet is higher than hot rolling sheet. The thickness cold rolling sheet is less than 5mm, if the thickness is bigger than 5mm, it is the hot rolling sheet. Cold rolling have better ductility, because hot rolling have more has porosity and trachoma.

3.Tube performance

Tube is classified seamless tube and welding tube. Thick tube is seamless tube, the thin tube is welding tube. Stainless steel welding tube should be welded by SU304 DDQ, otherwise tube will break after spinning.

4. Specification

Sheet : 1m*2m, 1.24m*2.44m, 1.5m*3.0m

Tube : It needs to make mold to custom, the stainless steel tube must be DDQ standard, it can be made by deep drawing.

5. Common blank metal types

Aluminum : 1060 /1070/ 1100/3003 / 5052 / 5251 /5083/ 6061

Titanium : TA1 TA2

Steel : SPCC / DC03 / DC04 / Q235/ Q275/ Q345

Silver : IC-Ag99.99

Copper : C10 100 / T1

Brass : H62 / H65

Stainless steel : 201 / 304 / 316 / 310

Aluminium and steel are easy to spin as the ductility is good, TA1, TA2, H62,H65 need to heat to reduce spring back, the stainless steel is hard to spin, it needs more spinning force.

6. Special blank metal types

Hardox 400 GH3044 SUS310 SUS630 Inconel 718 Inconel 625 TC4 A286

Aluminum 2024/2A12/7075/5A06 (aerospace aluminium) Supperalloy ( high temperature alloy )

Except the aerospace aluminium series, other metal have higher tensile strength and hardness than Stainless steel 304, it needs to spin with heating.

Metal spinning technology >>

1.Sheet and tube spinning>

Metal spinning technology can be classified into sheet spinning and tube spinning according to the type of blank materials. The blank of sheet spinning is a sheet or disk, the blank of tube spinning is a circular tube. We can choose sheet or tube spinning process according to the ratio (diameter / height) of metal spun products, the big ratio of metal spun product is suitable to make by sheet spinning, the little ratio of metal spun product is suitable to make by tube spinning. If you use sheet spinning to make the deep cylinder that ratio is bigger than 5, it is easy to break when the material ductility is not enoungh.

2.Cold and hot spinning

Cold spinning can make the soft (common metal are used in consumer goods) and thin metal sheet or tube, but heating spinning can make hard (special metal are used in aerospace and special industries) and thick metal materials. Heating can make metal soft, the spin force is less by hot spinning when spin the same thickness of metal. So hot spinning is applied in the aerospace materials that is hard to form by cold spinning. Heating ways have High - frequency heating and gas heating, high - frequency heating is quickly, gas heating has uniform heat in the workpiece.

3. Thinning rate

Blank sheet will be thinning after metal spinning. Hand spinning thinning rate is 10% -25%, the CNC spinning thinning rate is 20%-50%, because CNC spinning can make work piece produce shear deformation.

Cylinder has conventional spinning and shearing spinning, Common the depth valve of cylinder is big, the thinning rate is big, when the depth is over 200mm, the thinning rate can meet 50%, thinning rate of deep cylinder is biggest .The cone is shearing spinning, the actual thickness after spinning = sin Aº * blank thickness. Necking will increase the thickness and expanding will reduce the thickness. Necking will increase the thickness and expanding will reduce the thickness.

4. Shape

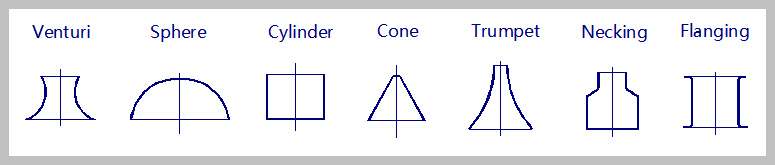

Metal spinning form tube and sheet to different shape, such as venturi, sphere, cylinder, cone, trumpet, flanging, compare to deep drawing, the necking and tube spinning can make the shell into more shape base on the following of shape.

5. Tolerance>

Metal spinning accuracy is related to the tensile strength of structure, the accuracy of CNC metal spinning machine tool, process temperature, material performance, spinning path, mold design. Metal spinning tolerance can meet 0.1mm at most. There is many ways to control the metal spun accuracy in the production.

● Mold and roller runout : it must control within 0.03mm, otherwise the spinning gap is not stable.

● Process temperature : metal spinning is a cold working can make the workpiece rise the temperature, to control the process temperature can improve the accuracy .

● Spinning path : using the right spinning path can make the production accuracy stably.

● Structure : the strength of the structure design can reduce the spring back effect the accuracy.

● Material : different material has different spring back performance, the springback is less, the accuracy is better.

Metal spinning needs mandrel (it is also called mold), the exterior curve of mandrel is same with the interior curve of metal spun product. Mandrel function is to support the sheet or tube, the surface of mandrel is smooth, the exterior of metal spun products is smooth. Mandrel needs hard steel and heating treatment to improve the surface hardness, if the hardness is not enough, the interior of metal spun product will be scratches when it spin the stainless steel or harder metal.

Roller hardness meet HRC-58, the roller wear quickly when it spin the stainless steel or harder metal, commonly many factory use electroplate harder metal on the roller surface after heating treatment to achieve the higher hardness. The rollr hardness is higher, the exterior of metal spun product is smoother.

Spin forming methods

1.Shear and Conventional

● Conventional spinning : the shape of the blank changes, the diameter may increase or decrease, but the thickness remains basically the same or has a little change. Convenient Spinning is similar to deep drawing forming, so it is also known as deep drawing, it is used to form the cylinder.

● Shearing spinning : it does not change the outside diameter of the blank, but by changing its thickness to make a variety of axissymmetric thin-wall parts such as cones. The characteristics of shearing forming method are that the rotating roller has less force, the material flows smoothly, the surface finish is high, the forming precision is high, and it can easily form the material which is difficult to form by ordinary spinning. When the cone angle is bigger than 20º, it can be made by shearing.

● The difference between conventional and shearing : The workpieces is only pulled by roller in the conventional spinning, but shearing spinning roller will press the workpiece on the mold. The grain of conventional spining will lengthen, but the gain of shearing will shear deformation.

2.Necking, Expanding, Rolling and Flanging

Necking, expanding, rolling and flanging are used in tube spinning commonly, many metal spinning products are used necking and expanding, such as automobile part three-way catalyst and air spring shell, metal vase, head, hydrogen and oxygen tank. Rolling is used to improve the strength and make the edge smooth, flanging is used to assemble different part together by screw, flanging forming is a good ways instead of traditional welding flanging, it reduces the welding and polishing cost.

3. Flow forming

Flow forming is a precision forming process in which the cylinder billet is installed on the mandrel of the spinning machine. The mandrel and billet rotate synchronically driven by the spindle, while the rotating wheel contacts the billet and feeds along the mandrel axially, resulting in plastic deformation of the billet, resulting in wall thickness reduction, diameter increase and length increase of the cylinder. This process is mostly used for processing thin-walled hollow rotary parts, such as rocket engine shells, hydraulic cylinders and high pressure vessels.

Metal spining machine

1. Hand spining lathe

Manual metal spinning lathe is simple (it is also called hand metal spinning machine), it is mainly composed of headstock and tailstock, tailstock is a air pressure cylinder used to clamp, the headstock is to assemble the spindle to turn. The price of hand spinning mahine is about 900 dollers - 2200 dollars.

2. CNC metal spinning machine>

With the development of CNC metal spinning machine tools, hand spinning is reduced and replaced by CNC, CNC metal spinning machine tool can output stronger spinning force and control the accuracy easily. The basic machine structure is similar with CNC turning. the difference is CNC metal spinning machine needs stronger spinning force and quicker feed speed than CNC turning, so the motor, guide rail and lead screw of CNC metal spinning machine is bigger than CNC turning lathe.

● Machine cost and price

CNC metal spinning machines have many types, the light-duty machine is about 4500 dollar, the heay-duty is more expensive, such as the 800 double roller that can process 800mm blank diameter, the thickness of stainless steel can meet 3mm, the price is about 48,000 dollers. Double roller is more expensive than single roller, heavy duty is more expensive than light duty, the specification of CNC metal spinning lathe is bigger, the machine cost is more expensive.

How to choose a right CNC metal spinning machine >

● Single roller and double roller

CNC metal spinning machine have single roller and double roller, double roller works more balance than single roller. Thinning rate of double roller is bigger than single roller as the pull and press force of double roller is biger, but the accuracy of metal spun products is better that is made by double roller.

● The function of CNC metal spinning machine components

Spindle motor power : spindle force

Axis motor power and leading screw specification : spinning roller force

Hydraulic pressure of tailstock cylinder : friction force of sheet

Harder, thicker and bigger diameter needs heavy duty metal spinning machines, it needs stronger spindle force and spinning roller force to deform.

Softer,thinner and little diameter needs light duty metal spinning machine, it works more fast with a high spindle speed and feed speed.

● CNC spining path and program>

Spindle speed : spindle speed is higher, the thinning rate is less .the surface is more smooth.

Feed speed : the feed speed is high, the thinning rate is less, the surface is worse.

The radius of roller : the radius is bigger, the thinning rate is less, but the edge of sheet is wrinkling in the spinning. the radius is little, the thinning rate is bigger, the bottom (near the mold surface )of the sheet is easy to break in the spinning.

CNC spinning path : this is most important factor in the spinning, right CNC spinning path can form the sheet with a good surface and precision.

CNC spinning roller : a tool to deform the metal sheet or tube.

Metal spinning roller post : a tool to assemble the roller to the machine.

CNC turning parting tool : a tool use to turning the edge after finishing metal spinning .

Air pressure device : It help metal spinning product to demold .

Blank shelf : it is used to control and put on the blank sheet in the center of spindle .

Heating equipment : high frequency heating equipment and gas heating tanks .

Tube spinning fixture : it is used in tube spinning to hold the tube tightly .

Application >>

Metal spinning is wide applied in different industries, metal spinning can process complex shape, thicker and bigger blank sheet, high accuracy and strength, these advantages make metal spinning play a irreplaceable role in the manufacturing.

● Tensile strength : these components need to bear force such as oxygen tanks ,pressure container and bottle.

● Complex shape forming capacity : it applied in decoration, such as lampshade, table base.

● Large dimension : it applied in industrial fan, industrial funnel, firebowl.

● Special metal : the special metal material are working in a rugged environment such as high temperature, vibration, high speed and bearing the force. Special metal and heating metal spinning is better choice for military and aerospace industries.

Metal spun products >>

1. Lampshade

lamp shadow is the most prolific product produced by metal spinning, most of lampshade materials is used steel and aluminum, these two material is soft to spin, many Indian and Vietnam factory make lampshade shell by hand spinning.

2. Tableware and vase

Stainless steel tableware, vase, bottle and pan can be made by metal spinning.

3. Auto parts

The air spinning shell, three-way catalyst, wheel are made by CNC metal spinning, the wheel CNC metal spinning machine is a hydraulic power spinning, metal spinning can improve the tensile strength of blank casting wheel and reduce the weight of wheel.

4. Industrial fan

The dimension of industrial fan is big, common the diameter of industrial fan is over 300mm. It need metal spinning to save mold cost, now no-mold metal spinning applied in industrial fan maturely .

5. Combustion chamber and nozzle

Combustion chamber, nozzle and fairing are the key components in the turbojet, the working temperature is very high, Nozzle working temperature can achieve 700ºC, it is used the Inconel 718 and Inconel 625 to make the nozzle, the combustion chamber working temperature can achieve 1600-2200ºC, it is used the superalloy to make the combustion chamber, supperalloy is also called high temperature alloy.