How to design a CNC metal spinning mold | mandrel

CNC metal spinning mold ( mandrel )

Many people don't know how to design the CNC spinning mold (it is also called mandrel)when they touch CNC spinning in the beginning. Spun mold and spun roller are basic parts used in CNC spinning machine, every metal spinning product needs a interior mold, Spinning roller will make sheet form accordding to the path of the CNC program.

The mold design ways and steps introduction

Flange

Flange is a common standard part which is assembled in the spindle when you buy CNC spinning machine.

Metal spinning mold (mandrel)

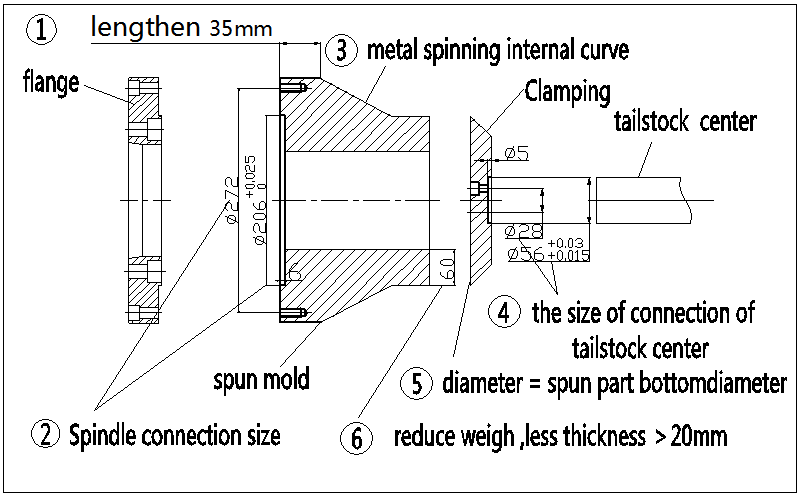

It is need to design accordding to different metal spun drawing .you can design it according the image, now we will introduce the function of very step in this image.

① Lengthen 30mm

Lengthen 30mm position is used to leave a position to put a CNC turning parting tool working after spinning, we usually spin the length will be pass the height of the drawing, then using a CNC turning tool to cut the extra edge.

② Spindle connection size .

Spindle connection size has two parts, Φ206mm is a location hole, Φ272mm position will have six screw holes .these is used to assemble on the flange.

Different CNC spinning machine have different location hole and six screw holes. you will find these size in the CNC spinning machine instruction when you buy machine.

③ Metal spinning interior curve

This is the actual interior curve according to the customer's drawing of metal spinning product.

⑥ Reduce weight

Reduce weight is good for the bearing of the spindle. If the mold is too heavy, the bearing will wear quickly.

There are two factor you need to think about in reduce weight. First, reducing weight must keep the uniform thickness of mold, it will reduce the stress focus and broken risk in the quenching. If the thickness is not uniform, the cooling speed of quenching is different, it is easy to broke. Second, the least thickness of mold is more than 15-20mm, if the thickness is too thin, the strength of the mold is less than spinning force, it is easy to break.

Clamp

Clamp is a part to offer the force of friction, thickness is 25-30mm.

④ The size of the connection of tailstock center

Tailstock connection size has two parts, Φ56mm is a location hole, Φ28mm position will have six screw holes .these is used to assemble on the tailstock.

⑤ Clamp biggest diameter

Clamp biggest diameter ≤ the drawing of the metal spun part.

⑥ Reduce weight hole

When the diameter of clamp is more than 300mm, you need to reduce the weight of clamping, you can design it like the image, but it must keep the gap is more than 30mm to make sure the strength of the clamping.

Common metal spinning mold design

● Separate mold

Some shape need to design separate mold to take off the spun product from the spindle mold, separate mold need to reduce the weight as it take off from spindle mold once spun in the production, less weight of separate mold can reduce the workload of staff, otherwise it need the crane to pull and assemble it.

● Eccentric mold

Eccentric mold is usually used in many container and bowl ,it use two bearings to assemble in eccentric mold bearing base, so eccentric mold can spinning with spinning roller.

● Neck spinning

It usually used in milk bucket spinning, the gap between spindle mold and the metal spinning shell is less than 0.5mm, otherwise you need to use a hydraulic fixturing instead of spindle mold.

How to choose the material of metal spinning mold

● 45# : if you spin copper, brass and aluminum, these metal are softer than 45#, you can choose the 45# as mold material, it don't need to make heat treatment. 45# steel is cheep and easily CNC turning and milling, it save mold cost.

● 40Cr : if you spin steel such as SPCC, DC04, DC03, Q235, Q275, you can choose the 40Cr to make mold, it is a little more expensive than 45#, 40Cr need to quenching to achieve higher hardness of surface.

● Cr12mov : if you spin stainless steel such as 304, 316, 310,or spin more hard metal, you need to choose Cr12, it is most expensive and hard to CNC turning, but it's HRC hardness can achieve 58.

If you choose material according to instruction above, the mold cost and mold life are good, if you choose the wrong material, the mold will break, wear and scratch quickly.

Recommended

- -Top twelve metal forming fabrication methods

2025-11-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27