Aircraft tail nozzle

- size:

Φ260*300mm

- thickness:

2.0mm

- material:

SUS310

- application:

military

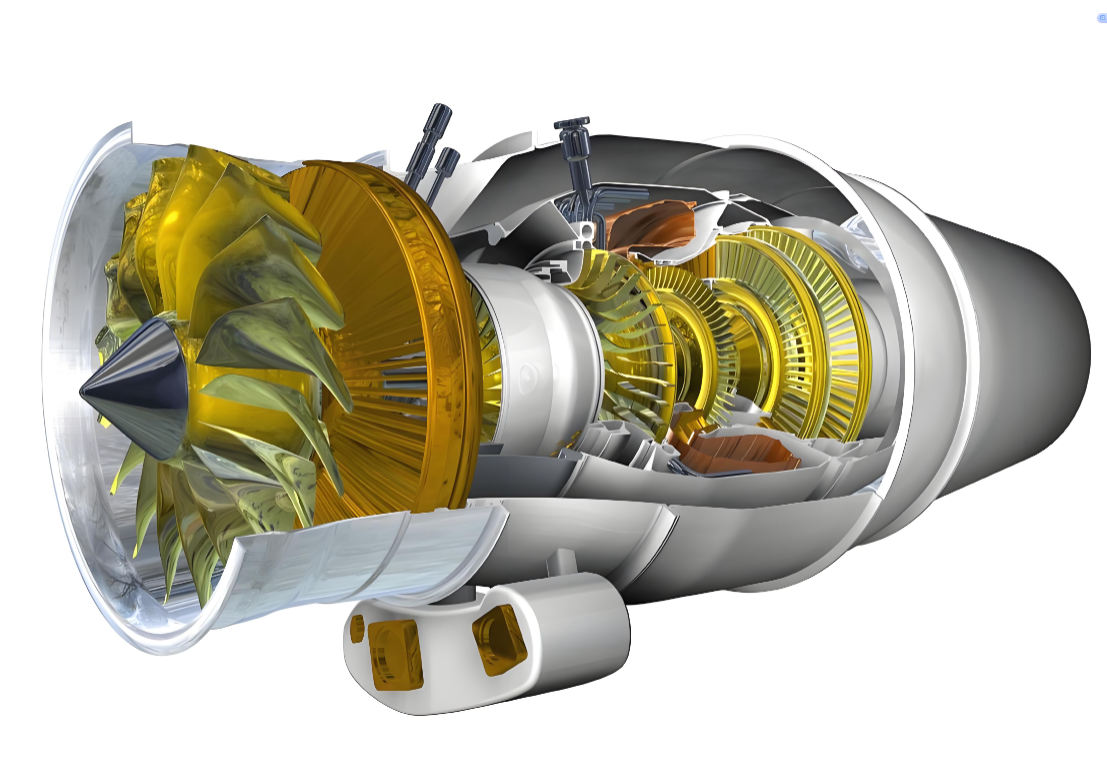

What is tail nozzle

The tail injection, short for tail nozzle , is a key component at the tail of an aerospace engine (such as the power system of aircraft, helicopters and other aircraft). Its core function is to convert the thermal energy of the gas inside the engine into kinetic energy, generating the thrust that propels the aircraft forward .

Manufacturing and processing

Due to the relatively high working environment temperature of tail spray, high-temperature alloys are commonly used for manufacturing. As the cost of spinning mandrel is low, the utilization rate of raw materials is high, and the processing accuracy is high, the manufacturing cost is greatly reduced.

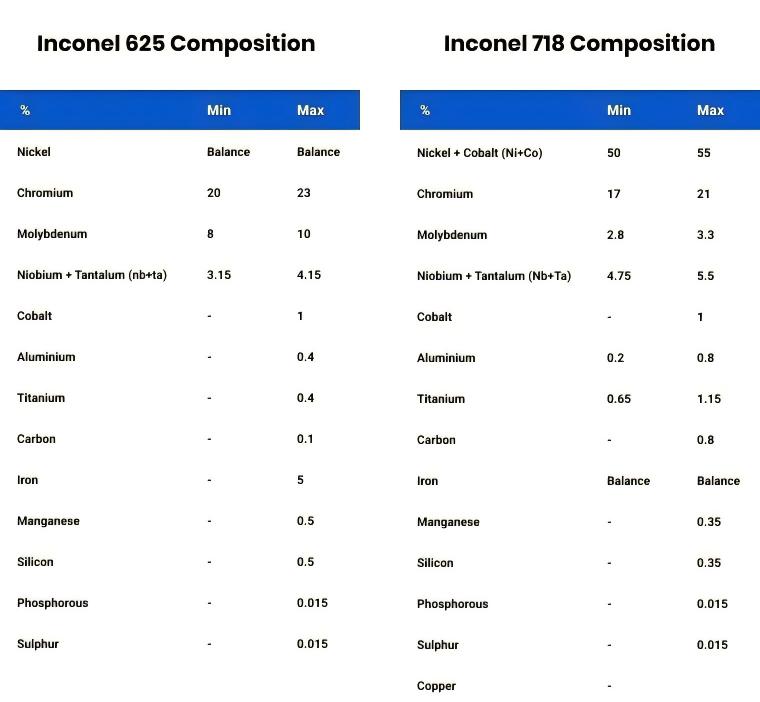

Inconel-Nickel-based alloy

Inconel alloy, as a nickel-chromium alloy, is highly regarded for its outstanding high strength, corrosion resistance and heat resistance. Among the numerous chromium-nickel-iron alloys, 625 and 718 stand out particularly. Although these two alloys share many commonalities, there are also some key differences between them. Next, we will delve into these two alloys to help you make a wiser choice and meet the requirements of your project.

Inconel 718 VS Inconel 625

Although both of these alloys fall within the category of nickel alloys, the types and proportions of chemical elements they contain are different from each other. It is precisely these differences that constitute their unique performance characteristics. Alloy 625 is mainly composed of nickel, which builds its nickel-based properties, while alloy 718 is based on nickel and adds cobalt, forming a nickel + cobalt (Ni+Co) -based alloy structure. This difference in composition makes 718 alloy perform exceptionally well in terms of hardness and strength. Relatively speaking, 625 alloy is superior in corrosion resistance due to its higher chromium and molybdenum content.

Performance and Application

The two alloys, Inconel 625 and Inconel 718, although sharing many common properties such as high strength, easy weldability and corrosion resistance, their differences in chemical composition endow them with their own unique application advantages. Inconel 625 is often used in the oil and gas industry due to its excellent corrosion resistance, especially performing well in underwater equipment. At the same time, it is also applicable to corrosive environments in the aerospace industry, such as exhaust systems, furnace mufflers and engine thrust reversers.

Alloy 718 has a wider melting range, reaching 1321-1393°C, which makes it perform well in terms of heat resistance. Alloy 625, on the other hand, exhibits superior corrosion resistance due to its rich content of chromium and molybdenum elements. On the other hand, Inconel 718 plays a crucial role in the aviation industry. Its excellent heat resistance makes it an ideal choice for high-temperature environments, such as in the manufacturing of engine components. In addition, it is also widely used in the manufacturing of high-performance automotive engines in the racing industry.

Inconel metal spinning

The tensile strength and hardness of Internickel 718 or 625 are both higher than those of 304, so the formability is poorer than that of 304. Usually, 718 and 625 need to be preheated. The material is heated to 200-300 degrees Celsius for spinning, the material will become softer and the metal rebound will decrease after being heated. The size and precision are easier to control.

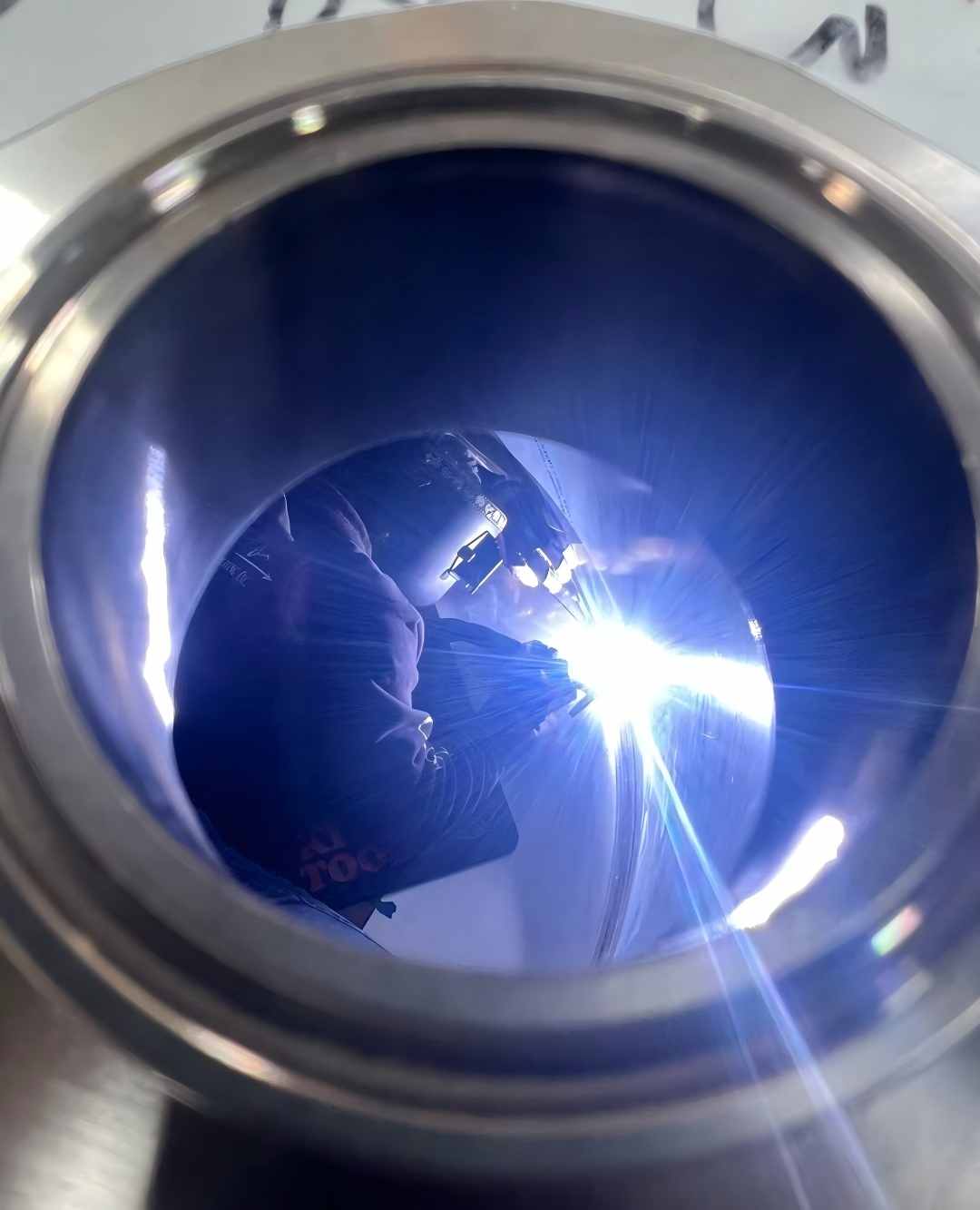

How to weld Inconel

Argon Arc Welding

Argon arc welding is one of the most commonly used welding methods for Inconel 718 or 625. By achieving low heat input welding through argon gas protection, it can effectively reduce the grain growth and softening problems in the heat-affected zone (HAZ). When welding, parameters such as current and welding speed need to be optimized to ensure the quality of the joint.

Electron Beam Welding

Electron beam welding is suitable for Inconel 718 or 625 components with high thickness and large area. It features high efficiency and low heat input. It can precisely control the temperature distribution and is suitable for welding complex structural components.