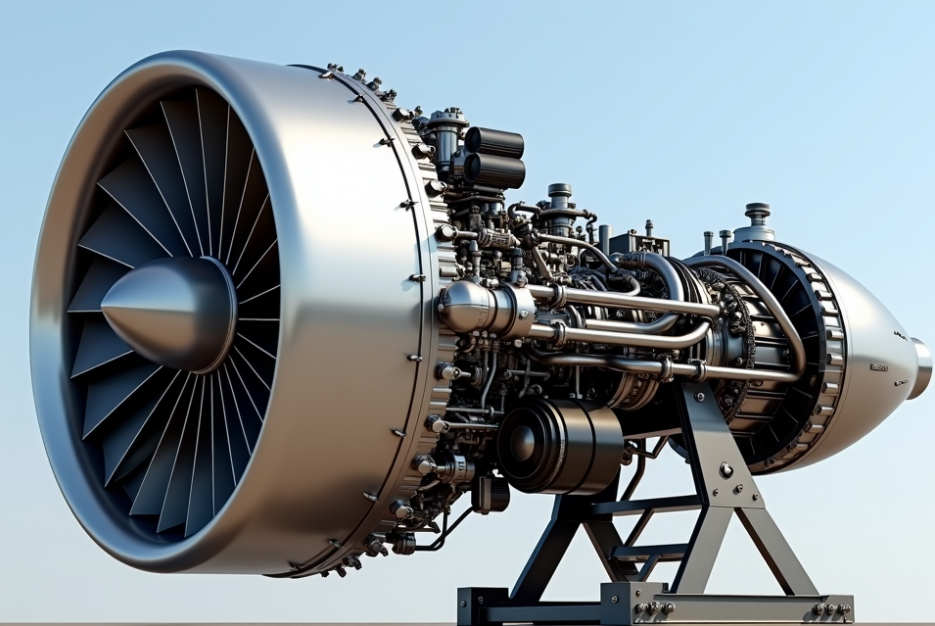

Turbine shell

- size :

270mm

- thickness:

2mm

- material:

2024 aluminum

- application:

airplane

Turbojet casing metal Spinning

Function

The main function of the casing of an aircraft engine is to rectify and reduce air resistance, as well as to protect the interior from electrical short circuits or failures caused by rainwater.

Material

The casing of a turbine engine is generally made of aluminum 2024 material. 2024 is often used to manufacture aircraft frames, skins, wing spars, spacers, rivets and other components, as well as missile structural parts and propeller components. Due to its high strength, fatigue strength and good machinability, it can reduce the weight of high-load components below 150°C by 30% compared with traditional materials.

Metal spinng performance

Aluminum 2024 needs to be formed in the O state. After spinning forming, its hardness can be increased to the T3 state. Its spinning performance is similar to that of 5052 material. It is best not to heat aluminum 2024 during spinning. After heating to 150°C, it is clearly felt that the material will undergo work hardening. Its forming performance is still quite good during cold spinning.

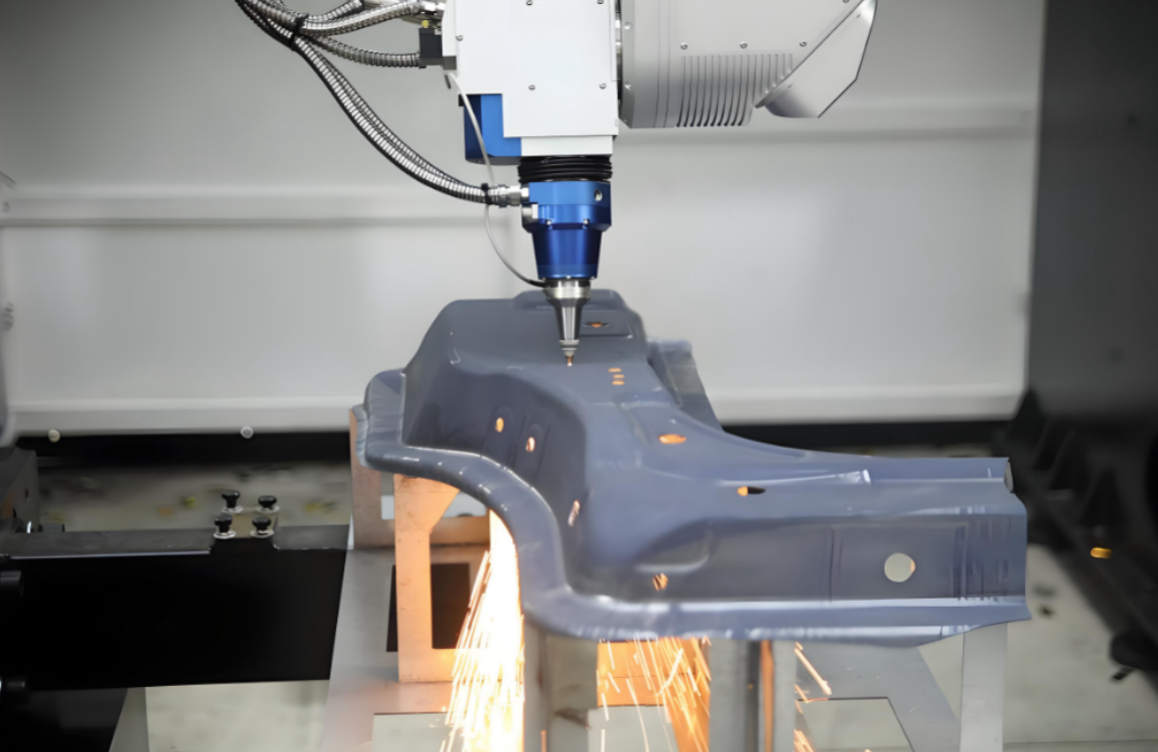

Precision control>

As an aviation part, the processing precision requirements for aircraft engine casings are still very high. The main precision controls include the curve accuracy, thickness accuracy, and diameter accuracy of the spun metal product. When detecting the diameter, since the spun parts are thin-walled parts, an ellipse will be formed after spinning, and it is difficult to inspect its true size with a caliper. The correct method is to use a go and stop gauge. Put the shell inside for inspection to meet the customer's needs. As for the detection of curve accuracy, a detection gauge can be used to cut out an external curve by laser cutting to determine whether the overall curve is consistent with the drawing.

Exterior polishing

The exterior of the spun part will produce uniform tool lines, so the surface of the shell needs to be polished to make the exterior surface smoother. At the same time, the polishing process should be controlled to prevent the wall thickness of the product from becoming too thin, which would affect the tensile strength and service life of the product.

5-axis laser cutting

Three-dimensional laser cutting uses the same fixture and programming software to complete multiple processing steps at one time, with good dimensional consistency and higher relative position accuracy of hole positions. In terms of speed, high-speed cutting far exceeds traditional methods, capable of cutting several meters of pipes in one minute. It can process complex shapes, is suitable for various materials and specifications, and does not require molds. Different shapes can be processed by changing the program. Efficiency and cost, it can replace multiple traditional processes, shorten the production cycle, reduce mold and labor costs, and has strong batch processing capacity.

Surface treatment

The corrosion resistance of aluminum 2024 is not very good. Usually, it needs to be painted or oxidized to enhance the material's corrosion resistance.