turbojet-turbine

- size :

130MM

- thickness:

1MM

- material:

Stainless steel 310

- application:

Aircrafts

Small turbine engine

A small turbine engine is a miniaturized version of a gas turbine engine. It generates power through the cycle of intake - compression - combustion - work. Its core structure includes a compressor, a combustion chamber and a turbine. Its typical characteristics are:

Size : The smallest model is only 10×15×15 cm (such as Honeywell MTJE)

Thrust : The KJ66 model for aircraft has a net thrust of 75 newtons

Application

Small turbine engines, with advantages such as high power density, fast response and fuel adaptability , have achieved breakthrough applications in multiple fields. The following are core scenarios and typical cases:

Unmanned aerial vehicles and aircraft

● Military reconnaissance/strike

The Turkish Bayraktar TB2 unmanned aerial vehicle is equipped with a Rotax 912 piston engine (turbocharged version), has a endurance of 27 hours, and carries precision-guided missiles

The US Spring-Blade 300 loitering missile is equipped with a micro-turbine engine, has a range of 10 kilometers and a hovering time of 15 minutes

● Industrial grade inspection

The CW-15D unmanned aerial vehicle of China Zongheng Co., Ltd. is equipped with a heavy oil turbine engine, can withstand high altitudes (6,000 meters), and has a 5-hour endurance. It is used for power line inspection

Special vehicles and ships

● Hybrid range extender

The Koensegg Gemera supercar is equipped with a 600cc micro-turbine generator, generating a power of 600kW, and can accelerate from 0 to 100km/h in 1.9 seconds

The military armored vehicle is equipped with the AGT1500 turbine engine (weighing only 1.1 tons), which outputs 1,500 horsepower and has extremely strong fuel adaptability

● High-speed boat power

The Swedish C32 AMG speedboat is equipped with a twin-turbo engine, reaching a top speed of 80 knots (148km/h) and accelerating from 0 to 50 knots in just 15 seconds

Distributed energy system

● Micro generator

Capstone C65 micro turbine (luggage compartment size), 65kW output, combined heat and power efficiency over 90%

The Japanese Bladon Jets hydrogen fuel turbine generator supplies power to remote base stations with zero carbon emissions

● Emergency power supply

Honeywell Parallon 100 (100kW) is used as a backup power supply in hospitals and starts automatically within 5 seconds

Integration of emerging technologies

● EVTOL flying car

The hydrogen turbine hybrid system of GKN Aerospace in the UK provides vertical take-off and landing power for the Lilium Jet

● Micro-missile propulsion

The turbine engine of Raytheon's "Spear" missile has a diameter of only 10cm, a thrust of 450N, and a range of 40km.

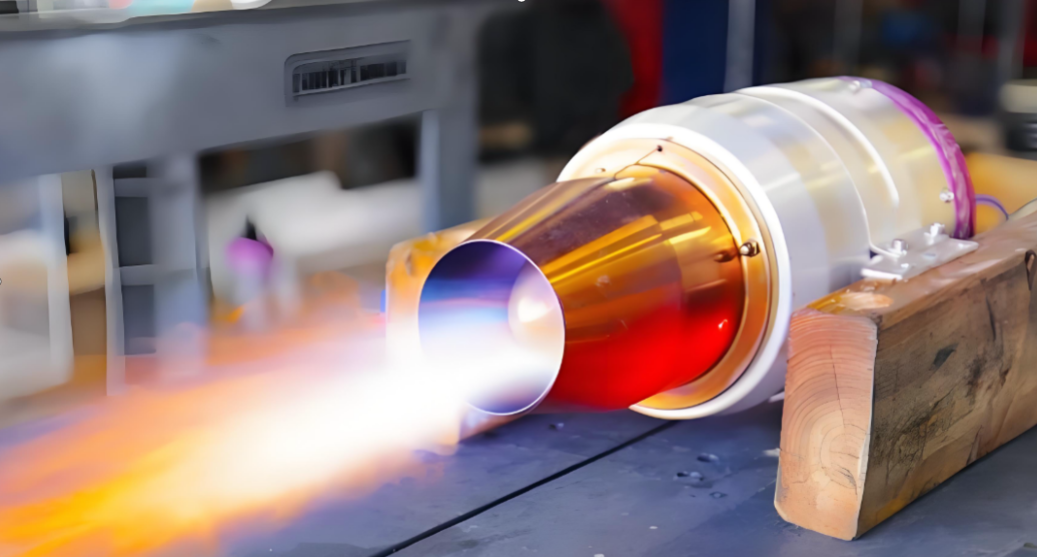

The metal spinning of the turbine engine housing

The casing of a turbine engine is generally processed by metal spinning. The grains of the casing are refined after spinning, and its tensile strength and hardness are enhanced. In addition, the manufacturing cost of the spin forming die is low, it is very suitable for medium and small batch production. The precision of the spinning diameter can reach 0.2mm. Due to the high assembly requirements of the turbine housing, it is necessary to conduct go- no go gauge tests on each spinning metal housing.

Five-axis laser cutting

Five-axis laser cutting is used for hole processing of the shell. It is difficult to ensure the relative position with traditional wire-electrode cutting, and five-axis milling machines are prone to vibration during processing. Therefore, choosing five-axis laser cutting is the best processing method.

5- axis CNC milling

The processing of small turbine engine impellers is a systematic project involving materials, techniques and inspection. It is necessary to lay a solid foundation from casting, achieve structural forming and complex surface processing through turning and milling, and then ensure accuracy with inspection and fixtures/tools, ultimately meeting the core requirements of the engine for impellers of "high precision and high reliability".