The spin forming performance and application of various materials

Metal spinning performance of different material

Many metal materials can be used for spin forming, For beginners in spinning, understanding the spinning performance and application of different spinning materials requires a period of study and practice. This article will introduce and analysis the spinning performance and application of various spinning materials indetails.

1.Aluminum : 1060, 1070, 1100.

Application : lamp shadow, decoration

Performance : low spring back and tensile strength, good ductility, excellent metal spinning performance

There are pure aluminum, It demonstrates excellent electrical conductivity, corrosion resistance and welding ability. Despite this, the tensile strength of this series of aluminium alloys is relatively low, and the performance cannot be strengthened through heat treatment. Pure aluminum have best spinning performance and ductility, it can be formed different and complex shape, good thermal conductivity make aluminum metal spinning shell are widely applied in lamp shadow or that housing needs heat dissipation. But the strength of the pure aluminum is not enough when it is used the structural components to bear force.

2. Aluminum : 3003

Application : signal reflector, outdoor lighting

Performance : outdoor and rust protection, good spinning performance

Aluminum 3003 have good spinning performance and rust protection, it is mainly used that metal spinning products works on the outdoor. Even though the spinning property is a little worse than pure aluminum, but the spinning forming is also excellent.

Although its strength is relatively low, it can be significantly enhanced through cold work hardening. It is worth noting that during the annealing process, this type of aluminum alloy may form coarse grains.

3. Aluminum 6061 or 6063

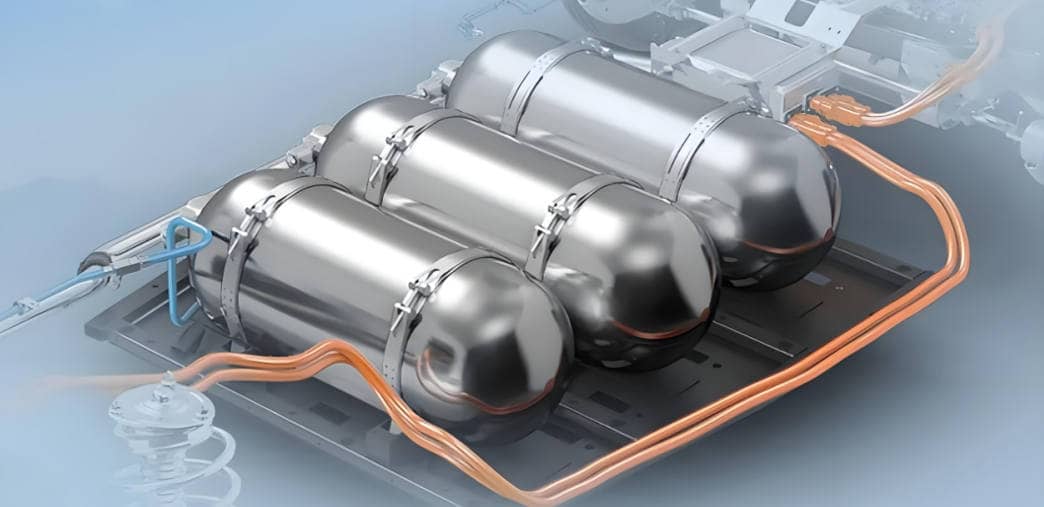

Application : oxygen tank and hydrogen tank

Performance : harder Hardness, excellent extrusion performance.

Alloys 6063 and 6061 are often used as ideal choices for extruded aluminum profiles due to their excellent extrusion performance. This aluminum alloy features medium strength, excellent corrosion resistance, good welding process performance and outstanding oxidation coloring ability. These characteristics make 6-series aluminum alloys widely used in the industrial field.

Aluminum 6061 and 6063 have good hardness and oxidation property, it is harder to spin than aluminum 3003, 6061 have higher tensile strength than 6063, they are commonly used to make the aluminum tube , if aluminum tube or section is made by other types, the hardness and strength is not good, so the sharp will deform and diameter accuracy is not good. Many oxygen and hydrogen tank are made by aluminum 6061, we need to spin the aluminum 6061 or 6063 in O state, the hardness of T6 state is hard and it is easy to break in spinning, using heating can increase the material flow and increase the tank thickness , then reach T6 state by aging heat treatment.

4. Aluminum 5052

Application : automobile components

Performance : excellent tensile strength, poor spinning performance

Aluminum 5052 have good tensile strength, it has bigger spring back than 6061 or 6063, so it is harder to spin than 6061 or 6063. aluminum 5052 is used to structural part, such as luxury car air spring shell are made by aluminum 5052 to bear the air pressure.

It cannot be strengthened through heat treatment but its strength needs to be enhanced through cold working. In addition, under the same area, The weight of aluminum-magnesium alloy is significantly lower compared to other series, which facilitates its extensive application across various conventional industries.

5. Aluminum 2024/2A12

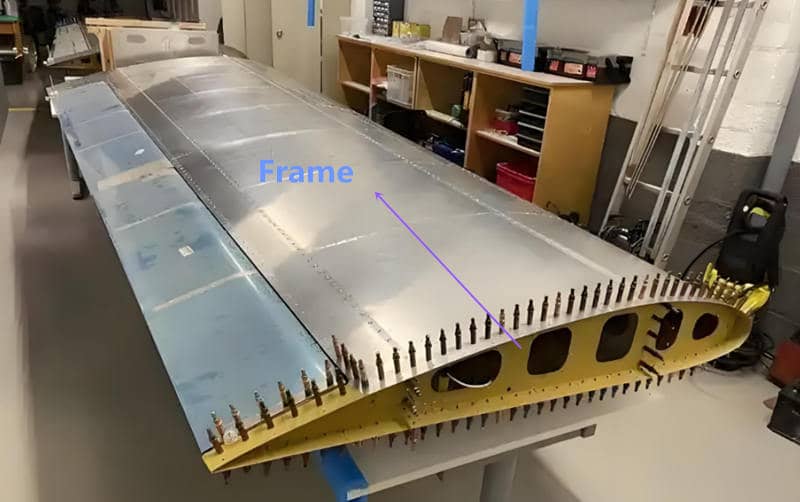

Application : aircraft skin, fairing, covering

Performance : poor corrosion resistance, excellent tensile strength and high temperature resistance, good spinning performance

Aluminum 2024 is a aerospace materials that is used in aircraft skin or covering, it has excellent formability and fatigue resistance, it can be spun by cold spinning , the tensile strength and deformation resistance is good, when you polish the the surface after spinning, you will find this materials will increase the tensile strength when the temperature increase. It is often used to construct key components, although it is not common in conventional industries. It contains 4.4% copper, 1.5% magnesium and 0.6% manganese, it is a heat-treatable high-strength aluminum alloy.

The high strength and heat resistance of 2024 alloy make it an ideal choice for high-temperature industries, such as casting truck wheels, etc. It can withstand extremely high working temperatures, ensuring the stable operation of equipment. It has relatively low corrosion resistance. Anodizing treatment, painting methods or adding an aluminum coating on the surface are often adopted to enhance its corrosion resistance.

6. Aluminum 7075

Application : aircraft frames and landing gears.

Performance : excellent tensile strength, poor spinning performance

Aluminum alloys 7075, as high-end choices in the 7 series, possess outstanding heat treatment strengthening capabilities. Compared with the 6-series alloy, although its extrusion speed is slightly slower, its welding performance is more excellent.

Aluminum alloy 7075 belongs to the Al-Zn-Mg-Cu series of aluminum alloys. It is a cold-worked forged alloy with high strength, surpassing that of soft steel. Ordinary corrosion resistance and good mechanical properties. Fine grains make the deep drilling performance better and enhance the wear resistance of the tool.

Inclusion

Spinning performance : aluminum 1060/1070/1100>3003>6061/6063>2024>5052>7075.

Springback : aluminum 1060/1070/1100<3003<6061/6063<2024<5052<7075.

Tolerance control : aluminum 1060/1070/1100>3003>6061/6063>5052>2024>7075.

The influence of heating on aluminum alloys

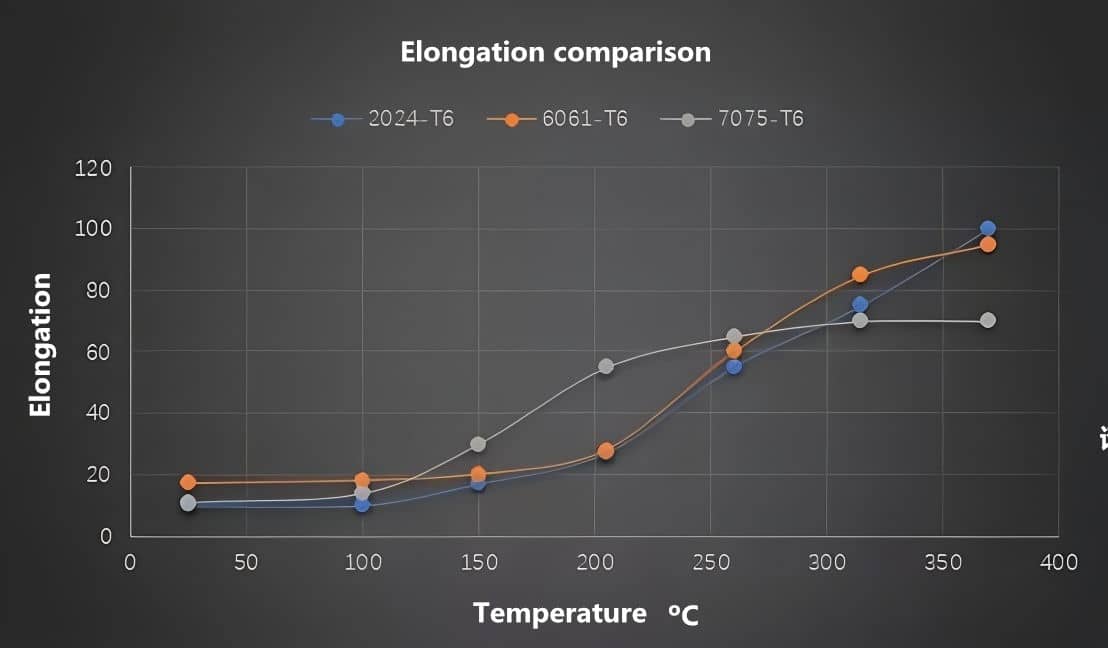

In this table, You will find the heating will improve the spinning elongation of aluminum 6061, 2024, 7075.

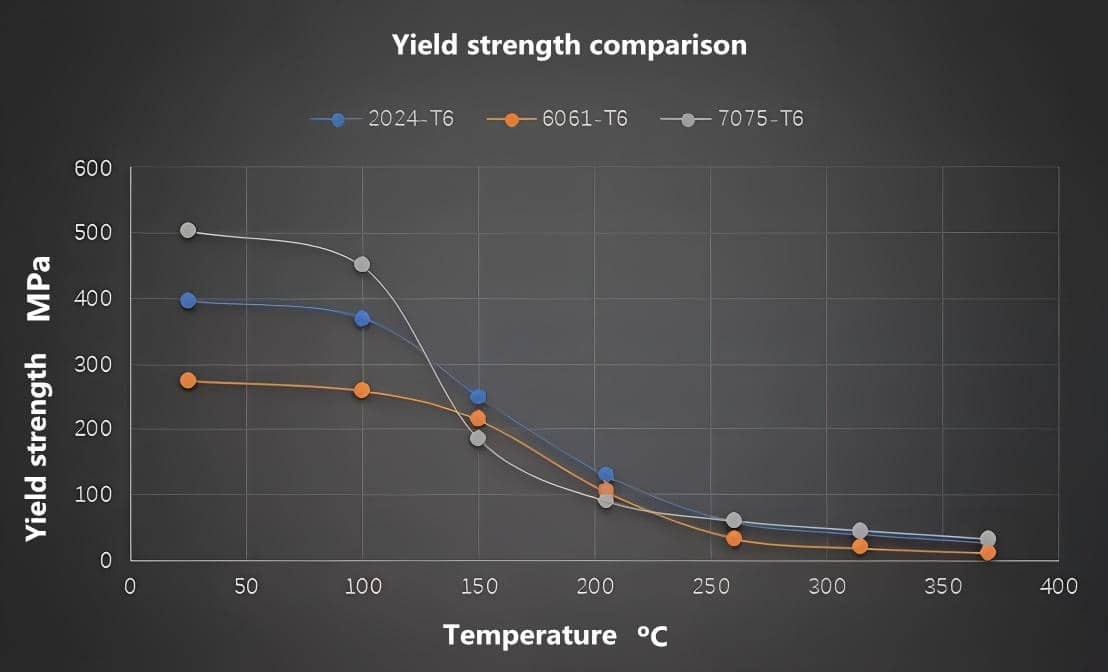

In this table, You will find the heating will improve the spinning performance of aluminum 6061, 2024, 7075.

7. Steel spinning performance and application

Performance : good spinning performance, poor corrosion resistance.

Steel is divided into mild steel, medium carbon steel, high-carbon steel, Such as DC03,DC04, SPCC, Q235, Q245, Q275,Q345 have the good spinning performance, These types all belong to mild steel, medium carbon steel 20 #, 45# steel have harder hardness , but it is also can be spun with heating, high carbon is rarely used for metal spinning.

8. Copper spinning performance and application

The spinning performance of the Tu1 and Tu2 is s close to pure aluminium, the ductility and spinning performance is excellent.

9. Brass spinning performance and application

Brass H65 and H63 is good to spin, but brass spring back is big, you had better to spin the brass with heating, it can reduce the tensile strength and the material becomes soft when it is heated.

10. Stainless steel spinning performance and application

There are many grades of stainless steel. Here we only introduce the properties of the commonly used stainless steel grades for spinning. SUS304 is the most commonly used material for spinning, 304 has excellent corrosion resistance, the spinning performance is harder than mild steel, the corrosion resistance and spinning performance of SUS316 are better than SUS304, the corrosion resistance and spinning performance of SUS201 are worse than SUS304. The temperature resistance of 310 stainless steel is better than that SUS201, SUS304 and SUS316, the spinning performance is similar with SUS201.

Regarding corrosion resistance, the materials of 201,304 and 316 have little difference in indoor environments. However, in acidic or coastal urban environments, the corrosion resistance of 316 is significantly better than that of 304, while the corrosion resistance of 201 material is the worst. 304 and 316, 304 and 316 are widely used in the food and household, tableware industries.

11. Titanium alloy

Ta1 and Ta2 is pure titanium, the spring back is bigger than 304, the hardness is softer than 304,the spinning performance is worse than 304. It used to make titanium tableware, outdoor bottle, pan. Titanium is beneficial to human health. Besides tableware, titanium is also used in various medical devices

The other titanium alloy is hard to spin by cold spinning, as the hardness is high and the ductility is poor, it need to spin by heating. such as TC4, TC4 titanium alloy is particularly widely used in the aerospace field. Due to its high strength, low density and excellent corrosion resistance, TC4 is used to manufacture key components such as aircraft engine blades, airframe structural parts and landing gear. These components need to withstand huge mechanical and thermal stresses, and TC4 titanium alloy precisely meets these requirements

Recommended

- -Top twelve metal forming fabrication methods

2025-11-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27