Top twelve metal forming fabrication methods

Metal forming technology

Metal forming is mainly used for the production of thin-walled metal parts, such as shells, containers, boxes, casing and other products. Metal forming technology is widely applied in manufacturing. The common metal forming methods we see include hydraulic stretching, spinning, water expansion forming, stamping, bending, pipe bending, aluminum extrusion, hot forging, and hand forging. For many purchasers and designers in the mechanical industry, they are not very familiar with these metal forming methods. This article will provide a detailed introduction to the above metal forming methods. By reading this article, you will have a good understanding of metal forming technology.

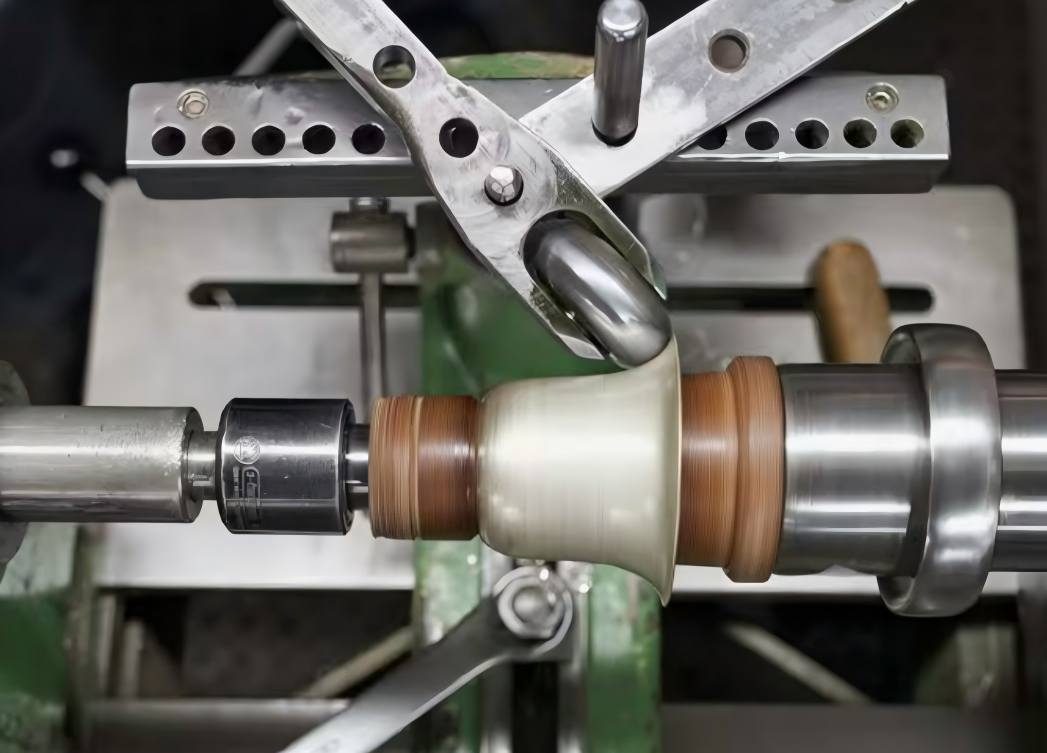

1. Metal spinning>

Metal spinning is mainly used to form thin-walled parts of rotating bodies. The main materials processed include aluminum, iron, copper, stainless steel, etc. Of course, it has an irreplaceable advantage in the processing of aviation and aerospace materials. The cost of spinning molds is relatively low and the sample period is fast. However, the production efficiency of spinning is not high, and it is very suitable for customized small-batch production.

Metal spinning VS deep drawing and hydraulic expansion

Nowadays, CNC spinning machines have become very popular. CNC spinning has higher precision, faster processing speed, and thicker products. Besides sheet material spinning, it can also be used for tube material spinning. Compared with other forming methods, the products made by sheet spinning are very similar to those made by deep drawing, and the products made by tube spinning are very similar to those made by water expansion forming. However, spinning is suitable for small batches and large diameters. The production of thick and hard metals, due to the extremely high cost of molds for stretching and water expansion, is an irreplaceable advantage of spinning.

Aerospace materials metal forming

Hot spinning can solve some metal forming problems with poor hardness and formability. For instance, many aviation and aerospace materials have high hardness and tensile strength. Traditional metal forming methods are prone to cracking, or the metal spring back is large, making it impossible to control the precision. Hot spinning heats the blank to different temperatures, increasing the fluidity of the metal and greatly improving the formability and ductility of the metal. At the same time, the hardness and resilience of the metal will both decrease, to produce the corresponding shape and precision as required by aviation.

The best mechanical performance

The hardness and tensile strength of the blank after spinning are greatly enhanced. Under the same wall thickness, the mechanical properties of spun parts are superior to those of other forming processes. This is why many products in the aviation field choose to use spinning. Spun parts are more stable in high-temperature or harsh working environments

The precision of metal spinning is relatively precision, and the surface finish is excellent. For instance, the Muti-roller flow forming machine can achieve a precision of 0.1mm.

If you need to customize high-precision spinning products, Dinnovation CNC Spinning Company> is a very good choice.

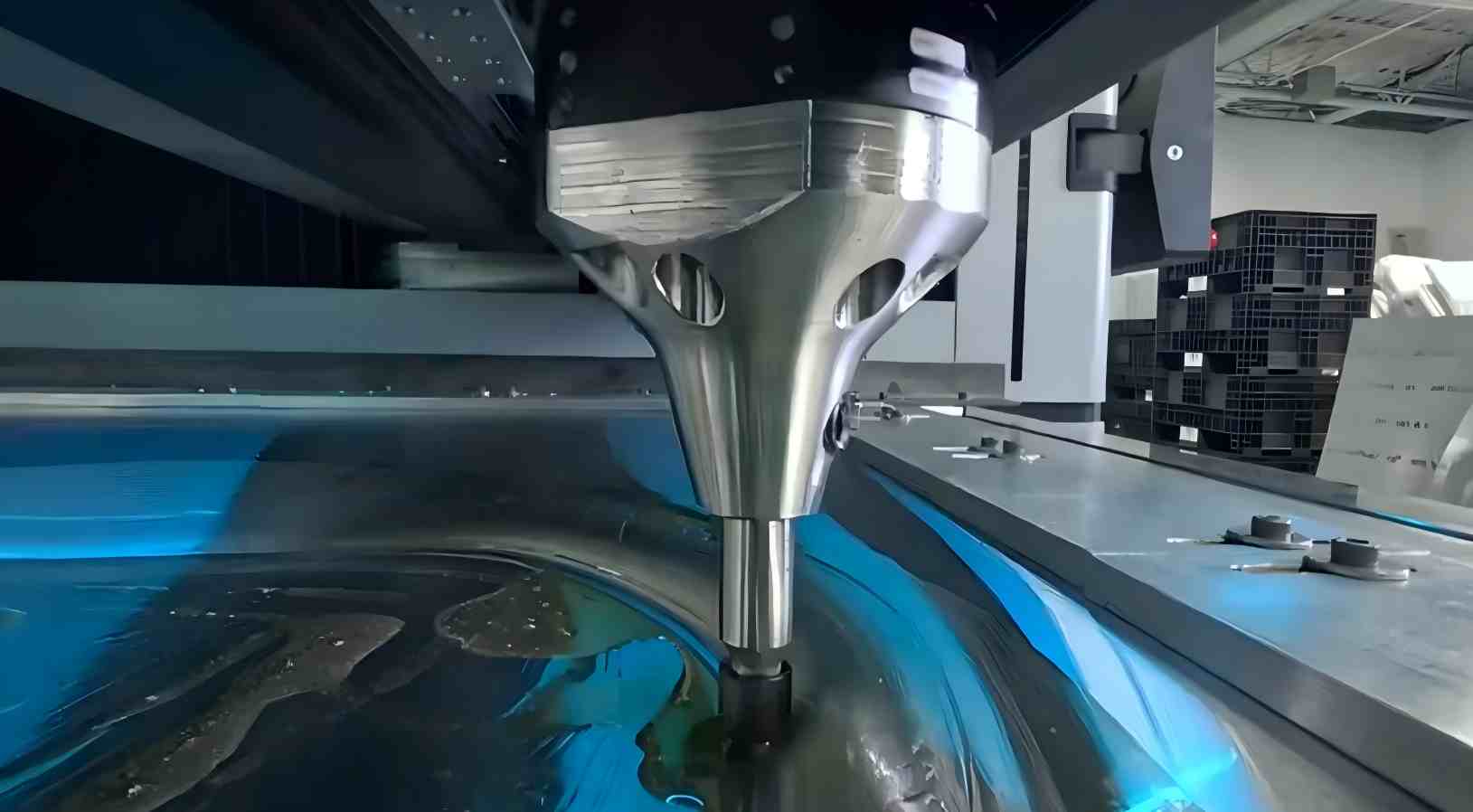

2. Sheet metal forming

Sheet metal forming is achieved by fixing the blank on a platform with two pressing plates and then extruding it into shape according to a CNC programming by a high-speed rotating tool.

Work principle

If the working principle of the metal spinning forming is similar with a CNC lathe, the working principle of sheet metal forming is similar with a CNC milling machine. The milling tools of a milling machine are used to cut the blank, while roller for sheet metal forming are used to extrude the blank.

Advantage

Sheet metal forming has significant advantages in the sheet metal manufacturing of high-end automobiles and hotel decoration. Although its processing efficiency is not as fast as that of deep drawing, it belongs to no-mold forming and has a fast development speed.

Precision and finishing

Sheet metal forming is numerically controlled. Despite the metal springback effect, the overall precision is still relatively high. There will be slight tool marks on the surface in contact with the tool, it is similar to the surface effect of spinning. The surface effect without contact with the tool is similar to the surface effect of deep drawing. The overall smoothness is still quite good.

3. Deep drawing

What is deep drawing

Deep drawing is a process that uses a hydraulic press to perform plastic deformation on metal materials and is widely applied in precision manufacturing fields such as hardware parts, automotive components, and home appliance shells. The core principle is that the pressure generated by the hydraulic cylinder stretches the metal material under a given temperature condition, achieving a wide range of deformation and precisely controlling the deformation variable.

Deep drawing VS metal spinng

Compared with metal spinning, deep drawing forming has a faster processing efficiency and lower manufacturing cost, but the deep drawing mold cost is 3 to 5 times that of metal spinning molds. Metal spinning can only form rotary bodies, which are traditionally referred to round objects. However, deep drawing can not only form rotary bodies but also produce square and various irregular-shaped parts, making it more capable in manufacturing product shapes.

Deep drawing problem

After the blank undergoes secondary deep drawing, it is prone to processing stress concentration; otherwise, the internal stress is likely to cause the workpiece to crack. High-frequency annealing is required to eliminate stress and soften the workpiece before further deep drawing can be carried out. The main problems in the deep drawing forming process are wrinkling and cracking of the workpiece, which are mainly related to the material flowing speed. If the flowing speed is too fast, local areas of the product are prone to cracking; if it is too slow, local areas of the product are prone to wrinkling. The entire forming process of the sheet can be controlled by adjusting the local shape of the die, the radius valve of the blinder, and the pressure of the hydraulic cylinder.

.

4. Stamping

Stamping is a very traditional forming processing method. It uses equipment such as presses to apply pressure to metal sheet materials, causing them to undergo plastic deformation or separation, thereby obtaining parts of the required shape and size.

In traditional manufacturing industries, stamping is mainly a tool for blanking and punching. The stamping machine works very efficiently and has a low processing. cost.

Many people do not know that stamping can also be used for deep drawing. Stamping is particularly suitable for products with small dimensions, low deep drawing depth values, and extremely large order quantities. Products produced by continuous die stamping are stable, and the processing efficiency is 2 to 3 times that of deep drawing. If the forming depth is too big, it is easily to break in the forming processing compared to deep drawing.

Continuous die

The continuous die structure design is complex, the manufacturing cost is high, the processing cycle is long, and both the processing accuracy and assembly accuracy requirements are very high.

Continuous dies can complete multiple processes such as blanking, bending, forming and drawing in one stamping stroke. Continuous stamping dies are more widely used in the fields of mobile phones, automobiles and other accessories. Among the continuous stamping machines, those from Germany and Japan are the most advanced. They can stamp 300 to 600 times per minute and control the precision of the products during the high-speed reciprocating motion of the machine tools.

Continuous stamping dies, with high efficiency and automation as their core advantages, are ideal choices for mass production, but their high cost and precision limitations need to be balanced. In practical applications, the mold type should be selected based on product requirements (such as batch size and precision)

5. Water expansion

What is water expansion

Water expansion forming (also known as hydraulic forming or internal high-pressure forming) is an advanced process that uses liquid as the force transmission medium to manufacture hollow metal parts by controlling internal pressure and material flow.

Water expansion can be used to form both flat plates and tubes. The core principle is to use pipes or plates as blanks and expand it from the inside out through ultra-high pressure liquid (such as water, oil or emulsion), making the material adhere to the mold cavity and thus forming complex-shaped parts in one step.

Plate water expansion

Pipe water expansion

Process characteristics and advantages

● High precision and high strength : Water expansion forming is a cold working process, with high dimensional accuracy of the product (up to IT12 grade or above), and as it is formed as a whole without welding, the structure is more solid .

● Reduce processes and costs : It can form multi-section parts (such as reducers, tees) in one go, reducing welding and assembly steps, lowering mold investment and material waste

● Widely applied : suitable for fields such as aviation, automobiles (such as body frames, exhaust pipes), bathroom (faucets, thermos cups), pipe fittings (tees, elbows), etc.

Water expansion VS metal spinning

Water expansion forming is more suitable for complex curved surfaces and thin-walled parts with high precision , while spin forming is better at manufacturing rotational symmetrical and high-strength parts, especially in scenarios where thinning or improvement of material properties is required, its advantages are obvious.

| Feature | Water expansion forming | Spin forming |

| Deformation mode | Uniform expansion overall, with relatively small changes in wall thickness |

Local squeezing, the wall thickness of ordinary spinning remains unchanged, while thinning significantly reduces the wall thickness of spinning |

| Applicable Materials | Pipe and sheet materials (Need good plasticity) |

Metal sheets (such as aluminum, stainless steel, titanium alloy, etc.) |

| Product shape | Complex curved surface parts (For example: kettle, cup) |

Rotating symmetrical parts (such as semi spherical and cylindrical parts) |

| Accuracy and surface quality | High dimensional accuracy and smooth surface | Surface quality depends on operational skills, suitable for medium to high-precision parts |

| Production efficiency | Can be molded into multiple pieces, with high efficiency | Suitable for small to medium batch production, with moderate speed |

Water expansion to make a sculpture

When we are outdoors, we need to weld a screw on the surface of the water pressure expansion type product, and then inject pressurized water to make it expand to obtain the desired sculptural shape.

After the surface has been polished, It can then be made into a very beautiful wall decoration piece. The application of water expansion is also very extensive in the hotel and construction industries.

6. 3D printing

3D printing (also known as additive manufacturing) is a digital manufacturing technology that creates three-dimensional objects by layering materials. In recent years, this technology has developed rapidly and has been widely applied in many fields such as medical care, construction, aerospace, consumer electronics

Application

Apple has used 3D printing technology on a large scale to manufacture titanium cases for the Apple Watch, using the "bonding jetting" process to reduce raw material consumption by 50%. The annual growth rate of the consumer 3D printing market is 28%, and it is expected that the shipment volume will increase to 20 million in the next five years.

3D printing is Used for personalized surgical guides, orthoses and prostheses, teeth in the medical industry.The 3D-printed turbojet engine developed by the Aviation Engine Corporation has 85% of its components 3D-printed.

Advantage

It can manufacture complex geometric shapes and internal structures (such as hollow components and honeycomb structures) that are difficult to achieve with traditional techniques, breaking through the shape limitations of traditional tools. A complete product with moving parts (such as a door and its hinges) can be printed out at one time, eliminating the assembly step and thus shortening the supply chain and reducing costs. No need for expensive molds, especially suitable for prototyping, personalized products and small batch production, 3D printing belongs to additive processing and has a high material utilization rate.

Disadvantage

Limited mechanical properties : There may be unmelted powder, microcracks or pores inside 3D printed parts, resulting in strength, wear resistance and fatigue resistance that are 20%-30% lower than those of traditional subtractive manufactured parts.

The work piece may still shrink or deform after cooling, this will result in the product's precision not being very high, requiring secondary processing by CNC machining. Additionally, the surface quality of 3D printing is not very good. It requires processes such as grinding and sandblasting.

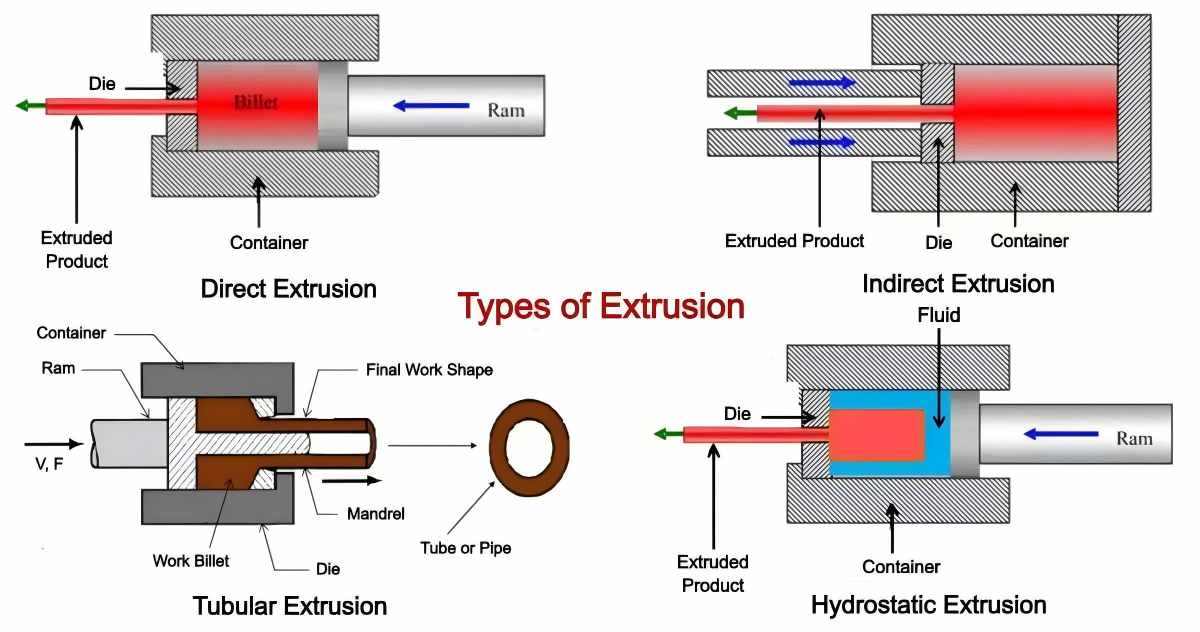

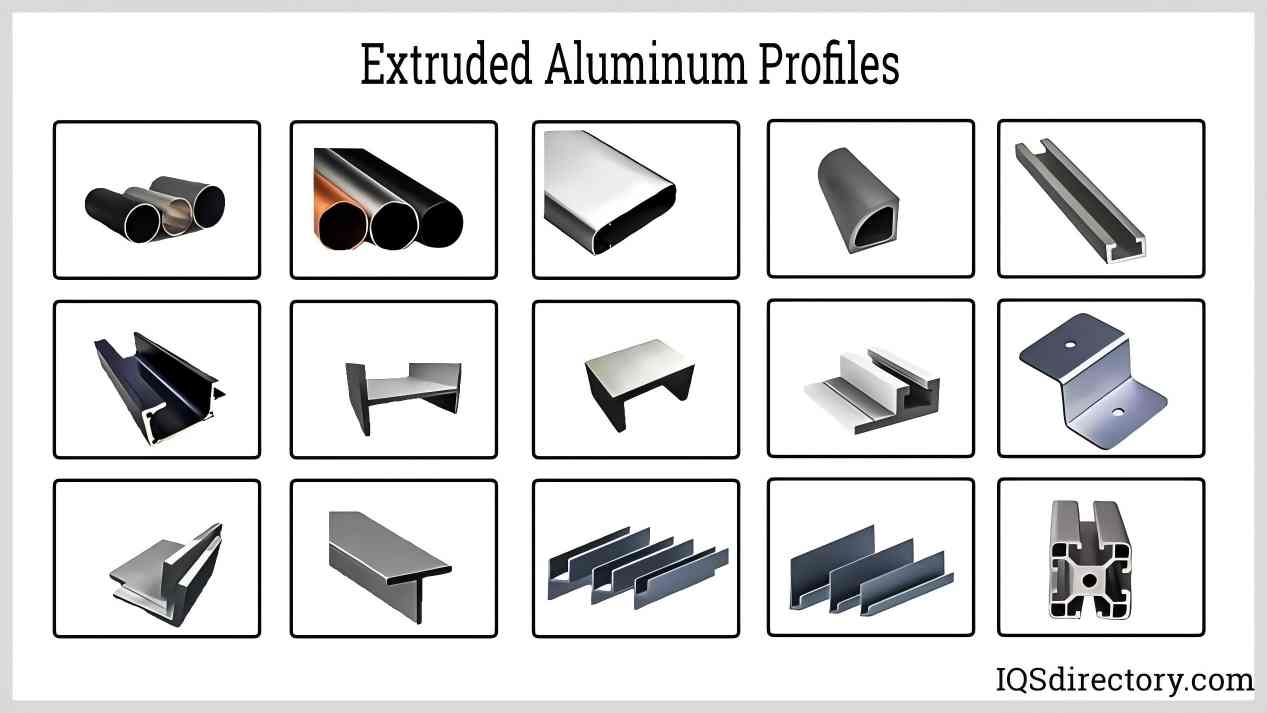

7. Aluminum extrusion

What is aluminum extrusion

Aluminum extrusion is a metal processing technique in which aluminum alloy billets are deformed and extruded into specific shapes by applying high pressure in a die through an extruder. This technology is widely applied in fields such as automobiles, construction, and electronics, featuring advantages like high efficiency, lightweight design, and flexible design.

Processing step

● Raw material preparation: Heat the aluminum ingot to approximately 480-540℃ to soften it.

● Extrusion forming: By applying high pressure through the extrusion cylinder and die, the aluminum billet undergoes directional deformation in the die cavity and is extruded through the die holes to form the required cross-sectional shape.

● Subsequent processing: including cooling, cutting, stretching, oxidation treatment, etc., to meet the performance requirements of different application scenarios.

Aluminum extruded state

Aluminum extruded profiles T1-T6 are different heat treatment state codes for aluminum alloy tubes, representing different mechanical properties and processing techniques. The following is the specific explanation

T1 : After high-temperature molding, it is naturally cooled to room temperature and then artificially aged. Suitable for scenarios that require high plasticity and corrosion resistance. T1 has good ductility to make by metal forming such as metal spinng, deep drawing, water expansion.

T4:after solution treatment and natural aging, it has medium strength and good corrosion resistance. T4 is suitable to make by bending.

.

T6 : After solution treatment and artificial aging, it has the highest strength, but some toughness may be sacrificed. T6 can be make by CNC turning and milling that can achieve good finished.

Performance comparison

Intensity and hardness : T6 > T4 > T1. The T6 state significantly enhances strength through artificial aging, but it may reduce ductility.

Corrosion resistance : T1 and T4 states retain better corrosion resistance due to natural aging, while T6 needs to be compensated for through coating or alloy optimization

8. Aluminum forging

What is aluminum hot forging

Aluminum hot forging is a precise forming process in which aluminum alloy billets are heated to a plastic state and then pressed into the mold cavity by external force of a forging machine. Its core advantages lie in high production efficiency, low unit cost, and significant improvement of the mechanical properties of the material.

Hot forging VS cold forging

Hot forging is carried out above the recrystallization temperature of aluminum alloy (usually 380-500℃), which is conducive to the plastic deformation of complex structural parts. It needs to be combined with the mold cooling system to control the grain size. When temperature is 200-300℃, it is suitable to form the Medium-precision parts.

Cold forging is beneficial for improving surface finish and dimensional accuracy, but it has a large deformation resistance and is mostly used for simple parts (such as bolts)

Advantages

Forgings refine grains and eliminate casting defects through plastic deformation. Their tensile strength is 15%-30% higher than that of castings, and their impact toughness is better . The surface of the forged part is free of pores and can undergo anodizing, spraying and other treatments to meet the corrosion resistance requirements

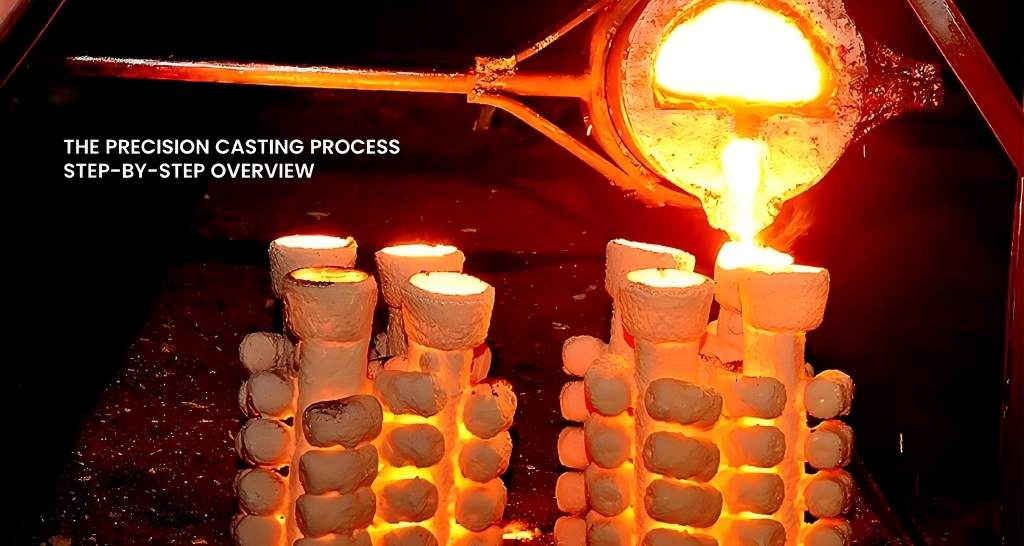

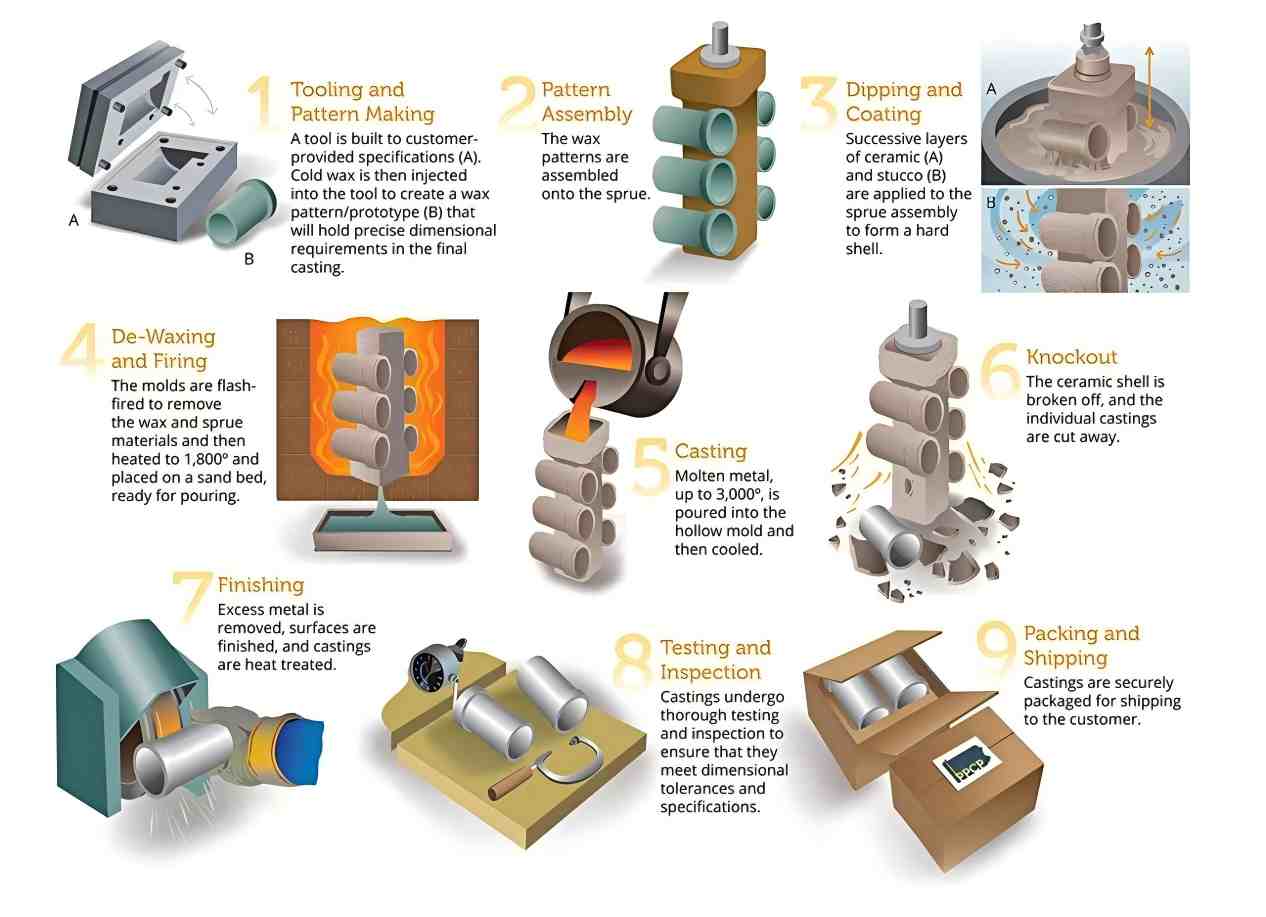

9. Precision casting

Precision casting (it is also called investment casting)is a technology that obtains high-precision castings through processes such as investment casting and pressure casting. Its products have accurate dimensions and smooth surfaces, and can be directly used in fields such as mechanical manufacturing.

The manufacturing steps

Advantage

The dimensional accuracy of castings can reach grade 4 to 6, and the surface roughness is as low as 0.4 to 3.2μm, enabling no-allowance manufacturing and reducing the need for subsequent processing . Complex-shaped, thin-walled (minimum 0.5mm) or small-hole (diameter <1.0mm) parts can be cast, with a wide range of contour dimensions (several millimeters to thousands of millimeters) . Applicable to various materials such as stainless steel, carbon steel, aluminum alloy, superalloy, etc., especially suitable for alloys that are difficult to forge or machine . It is suitable for both mass production and small-batch or single-piece manufacturing.

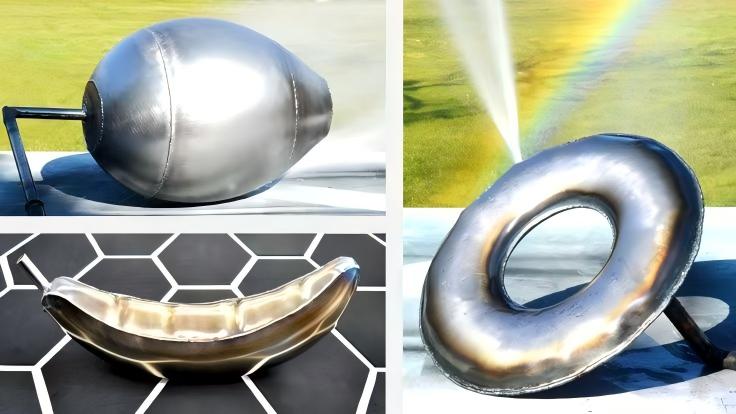

10. Hand forging

Traditional forging

When it comes to forging, many people will recall the ancient scenes in movies where people heated iron and then struck it with a hammer to make knives.

In contemporary technology, forging is an indispensable process for iron.In contemporary technology, forging is an indispensable process for steel. Many large steel materials are forged, but the process has gradually evolved from manual forging to machine forging.

Contemporary hand forging

The forging technique has been passed down from ancient times to the present. With the development of automatic and CNC machines, manual forging has become a very unpopular technology. Now it is mainly used in luxury car sheet metal, garden sculptures, and hotel decoration.

Stainless steel sculpture forging

Stainless steel sculptures commonly use stainless steel plates (such as 304 stainless steel and other corrosion-resistant materials). The thickness of the plate should be selected based on the size of the sculpture and the complexity of the shape (generally, the thickness of the plate for indoor and outdoor forged sculptures is controlled at 0.8-2.0 millimeters, and it can be thinner for small works).

If the shape is complex, a model will first be made of clay, then a plaster negative mold or metal mold will be made, and stainless steel plates will be placed on the mold to be hammered to avoid "bottomless running". If the shape is simple, it can also be directly hammered along the line on sandbags or other padding.

Large stainless steel sculptures (especially round ones) need to have their various plates joined together through welding , and the interior also needs to be supported by a steel frame to ensure stability. After welding, the weld seam needs to be ground flat with a hand grinding machine to make the surface smooth and flat. This step not only tests the technical precision but also determines the final texture of the sculpture.

Stainless steel forged sculptures have become one of the ideal means for indoor and outdoor sculptures due to their simple forming equipment and convenient manufacturing process , and they are more flexible compared to the casting method. Its "handcrafted" feature ensures that every detail embodies the craftsmanship of the artisans. It is not only suitable for large-scale public art creations, but also widely used in real estate sales offices, urban landscapes and other scenarios due to its light weight and easy mobility and installation.

Reshaping

Metal formed parts are all thin-walled and are prone to damage and deformation during transportation or storage. Manual forging can correct the deformed products.

11. Bending

Bending process is a forming technology in sheet metal processing that causes plastic deformation of metal sheets through external force, thereby changing their angles. Bending is an indispensable process in the sheet metal manufacturing industry.

Plate bending

Plate bending is most widely used in the sheet metal applications of rectangular chassis shells and equipment shells.

Pipe bending

● CNC bending

Elbow pipes, as key components for turning, connecting and functional extension in pipeline systems, serve production and life across industries and in multiple scenarios. The applications includes industrial production, building systems, transportation, home life, fitness and decoration.

● Hand bending

If the diameter and thickness of the elbow pipe are relatively small and the precision requirement is not high, a simple mechanical mechanism can be designed, and the elbow pipe can also be bent by hand.

Whether it is bending or pipe bending, the production efficiency is very fast and the processing cost is low. In terms of processing accuracy, both bending and pipe bending will be affected by metal rebound, which can achieve dimensional control by adjusting the mold Angle.

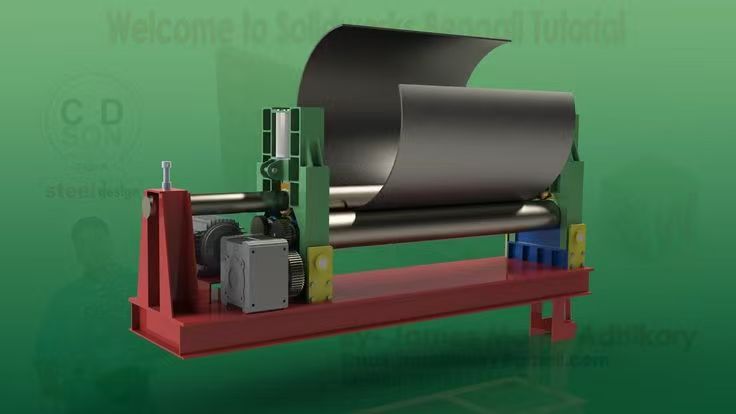

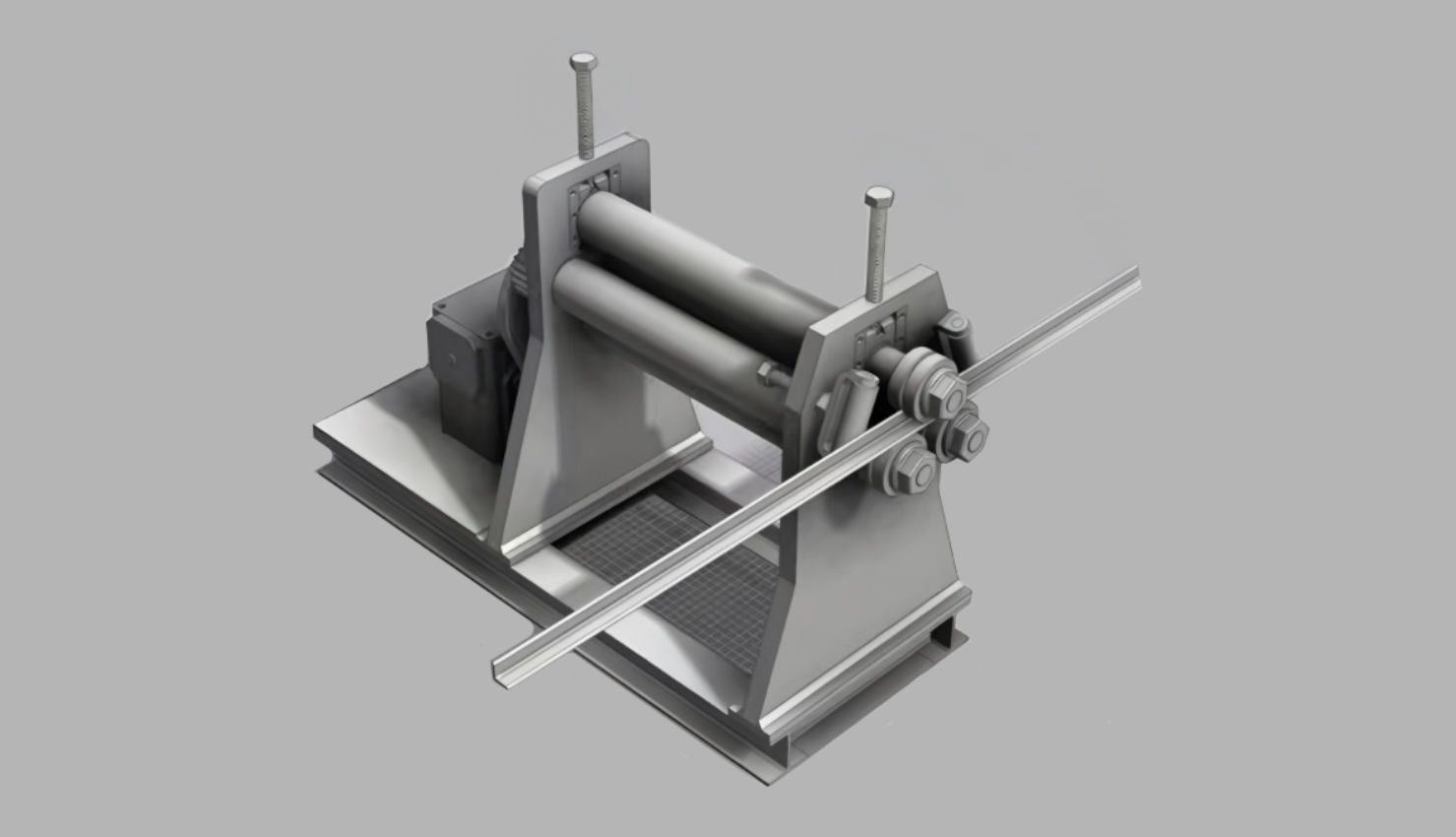

12. Rolling

Cylinder rolling

Cylinder rolling are widely used in fields such as tableware, pressure vessels, and pipes. Common types of plate roller machine includes three-rollers and two-rollers. Both two-roller and two-rolle are semi-automatic. The size of the roundness is controlled by adjusting the diameter of the pressure roller on the top. After the right mold diameter is adjusted, the speed of batch production is faster. Two-roller is more suitable for the production of thin materials. Three-roll machines are generally numerically controlled hydraulic, with greater forming force and are suitable for processing large-diameter and thick cylinders. When the thickness of the metal wall to be rolled into a circle exceeds 3mm, the edges are not easy to bend. Usually, a small arc corner needs to be folded at first with a bending machine, and then it is rolled into a circle with a rolling machine.

Cone rolling

Conical rolling is a process of shaping metal plates into conical workpieces, mainly achieved through plate rolling machines or dedicated conical rolling machines.The most commonly used cones are pressure vessels and funnels.

Tube rolling

Unlike the blank used for rolling circles and cones, the blank is plate or sheet, but the blank for rolling tubes is a round tube or pipe.

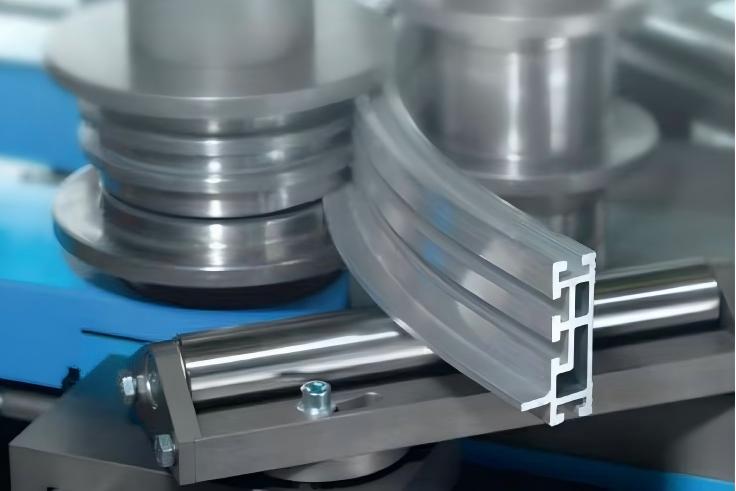

Extruded aluminum profiles rolling

In fact, the blanks of aluminium profiles can also be used to roll into circles.The shapes of the two rollers need to be consistent with the appearance of the aluminum profiles.

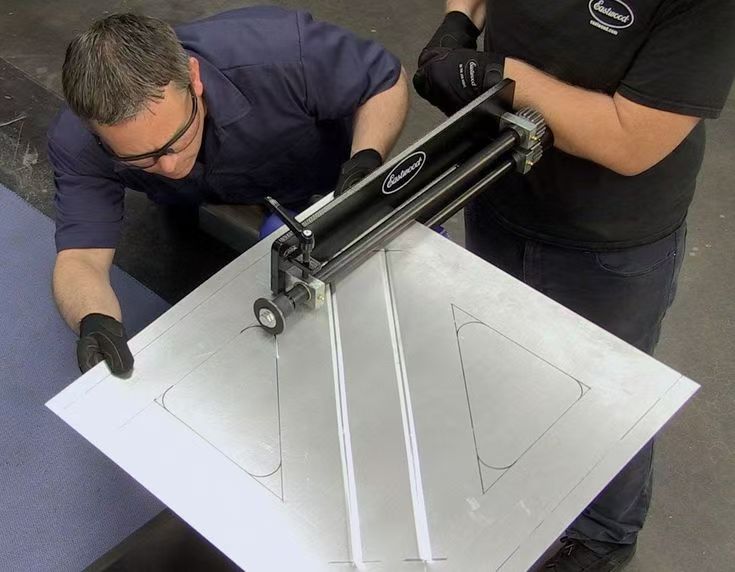

Bending sheet rolling

The bending blank can also be rolled into a circle. The principle of rolling into a circle is the same, but the shape of the rollers are different.

Curved bending

Roller is used in Surface shaping and weld seam shaping.

Rounded ribs rolling

To enhance the design of thin-walled parts, a rounded reinforcing rib is pressed onto the cylinder.

Plate ribs rolling

To enhance the structural strength of thin plate, it is also necessary to press some reinforcing ribs inside.

Having introduced so many methods of metal forming, I hope it will be useful for your project development and design. Hurry up and save them.

Recommended

- -Top twelve metal forming fabrication methods

2025-11-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27