How to draw the metal spinning tool path - Explanation of actual cases

Draw the spinning forming tool path

Many beginners in metal spinning often encounter some problems when you draw new spinning tool paths and programs of different shapes, such as cracking during the spinning process, wrinkling of the spinning outer ring, which leads to the inability to form the shape through spinning, or the precision of the final formed spinning product fails to meet the customer's requirements. This article classifies different spun products according to their shapes and introduces some practical techniques of spinning technology.

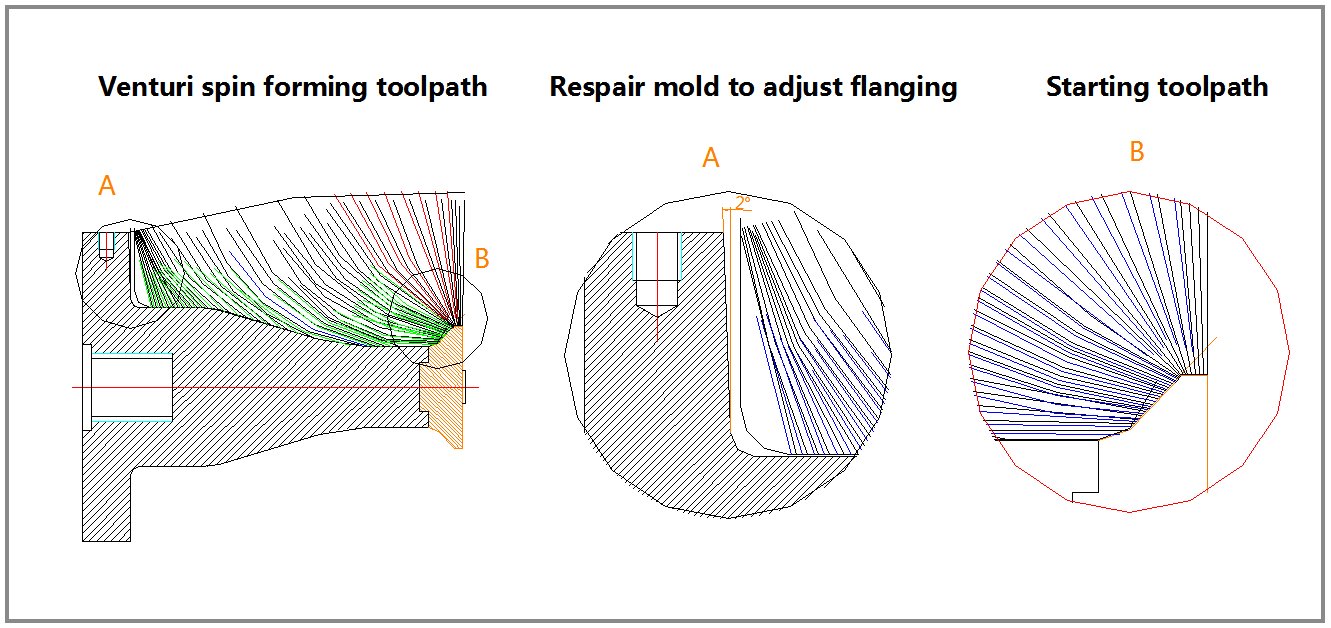

1. Venturi metal spinning

Venturi value is a device to control the air pressure and flow in the negative pressure laboratory.

● Spin forming tips

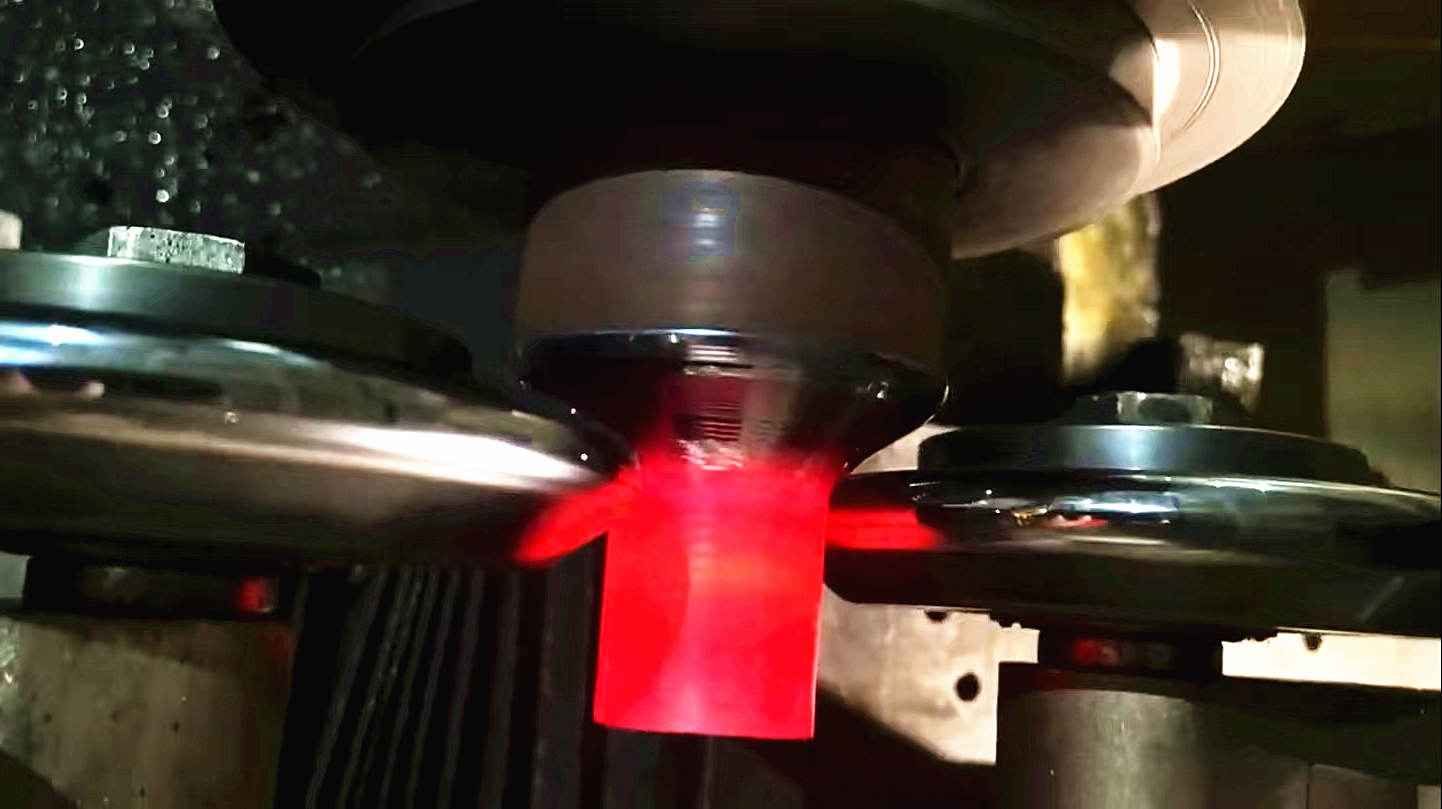

Venturi tubes come in various materials, including aluminum, iron, galvanized sheet and stainless steel. Among these material, the material of stainless steel 304 Venturi tubes is the most difficult to spin. The material of stainless steel 304 has low ductility and high springback. When the height of the Venturi tube exceeds 190mm, the root of the Venturi tube can hold to the mold tightly and is very likely to break. To ensure better adhesion to the mold, place the material sheet in front of the mold and heat it up. It is best to use a rice cooker for more uniform heating. On the other hand, using less gap between mandrel and roller to make workpieces hold the mandrel tightly.

Spin stainless steel venturi requires a stronger spinning force and double roller CNC metal spinning machine.

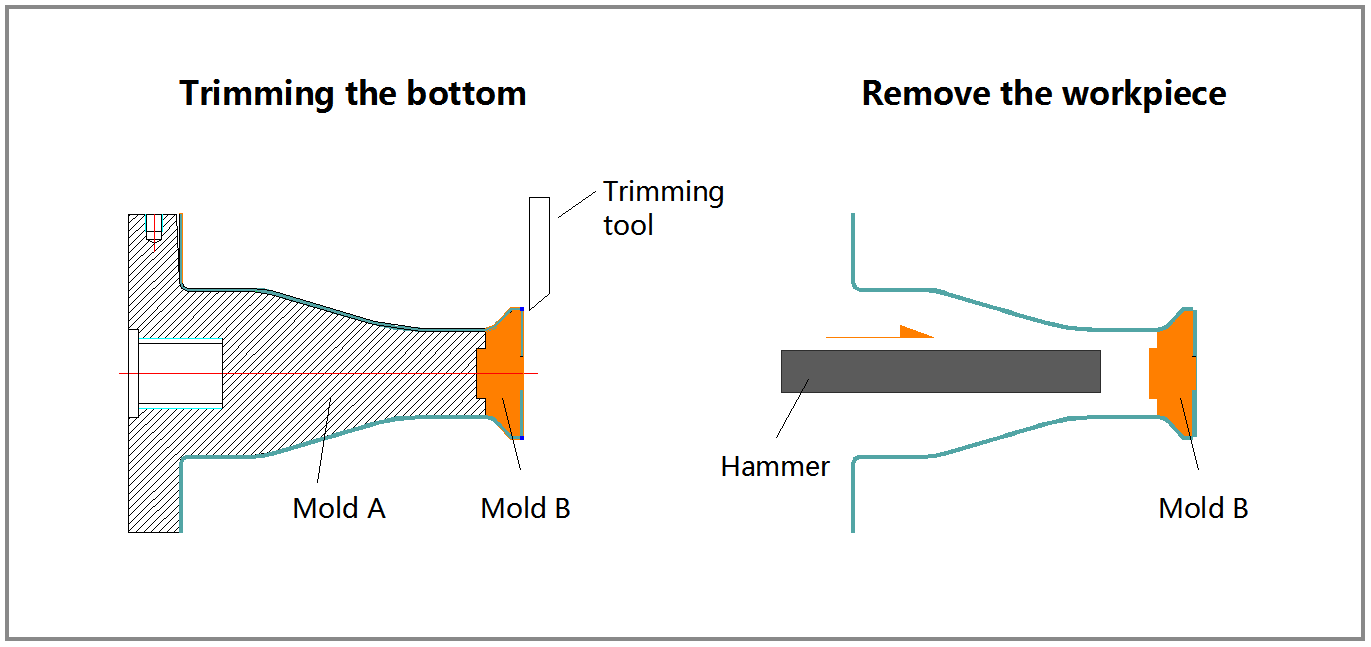

● Mandrel design and remove way

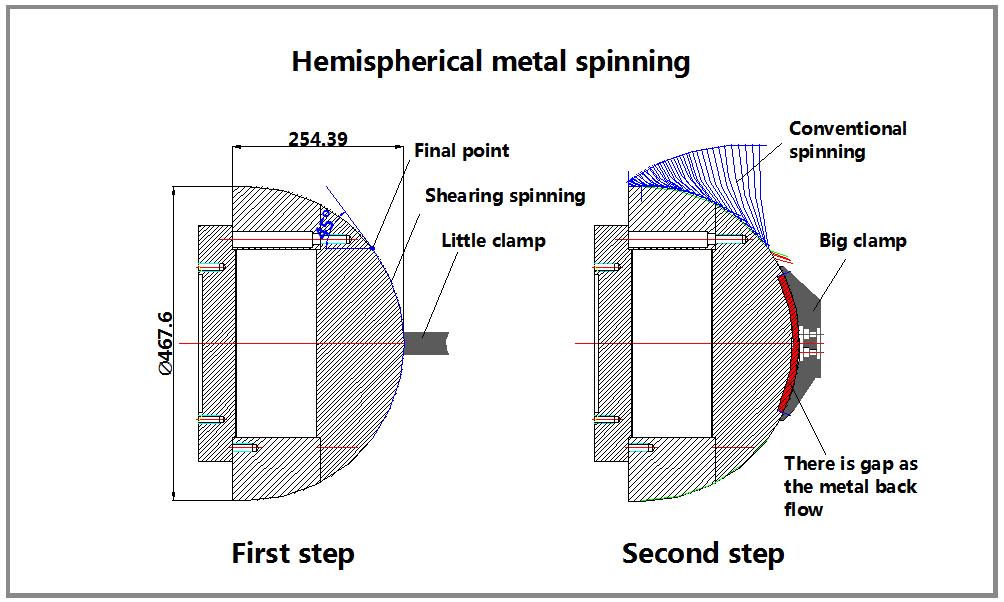

2. Hemisphere Spinning

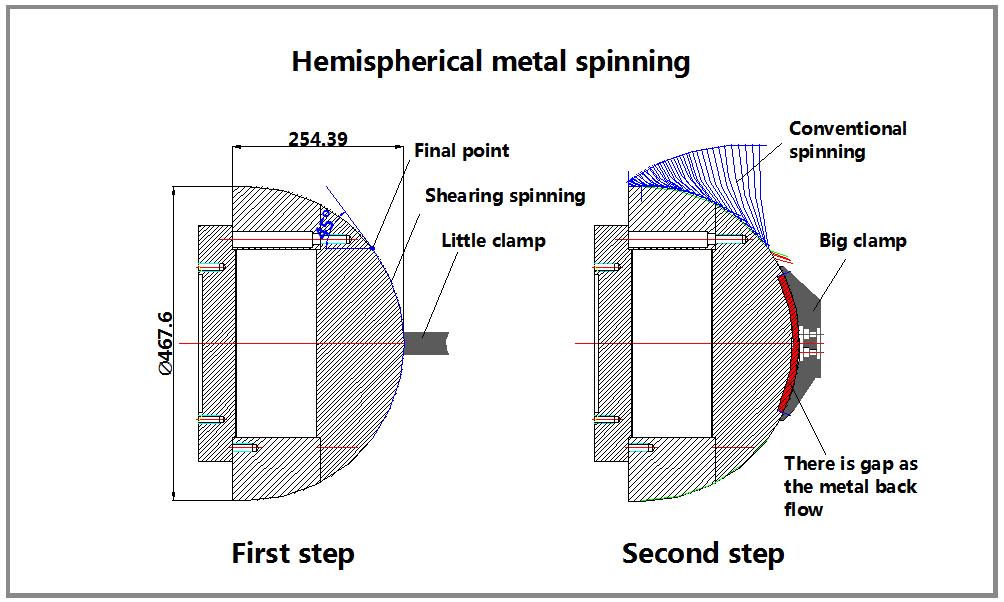

Hemisphere needs two clamps, to use the little clamp to form the bottom by shear spinning, the final point of shearing spinning will be end that The Angle between the tangent and the axis is less than 45 degrees. Or you can check the clamp wether can hold the workpiece tightly, it you find the workpiece move the relative the mandrel, you can adjust the final point is less than this position. You need to make sure the gap between the work piece and mandrel is less than 0.3mm. So second and big clamp can press work piece on the mold tightly.

To use the big clamp to make the second conventional spinning, this step needs more spinning force, the little clamp can’t hold the workpiece tightly. The feed point adopts an arc feed to avoid indentations at the feed point position. To control the right gap to avoid tight gap can make the metal back flow in the bottom of hemisphere.

3. Trumpet spinning

The characteristic of the horn is that the values of the large diameter and the small diameter differ greatly. Many beginner draw the tool path from small diameter to the biggest diameter of workpiece, it is wrong way that the starting position of the tool path is easy to break, because every path will pull this position and it will be thinning. In order to avoid this situation, we can use short path to form at the beginning. You can refer to the tool path drawing below, you can see it use the go path and back path, the main function of back path is to make workpiece to hold mold tightly. The final point of go path and path should preferablely not exceed half of the blank diameter.

Metal spinning path and parameter >

4. Milk bucket necking

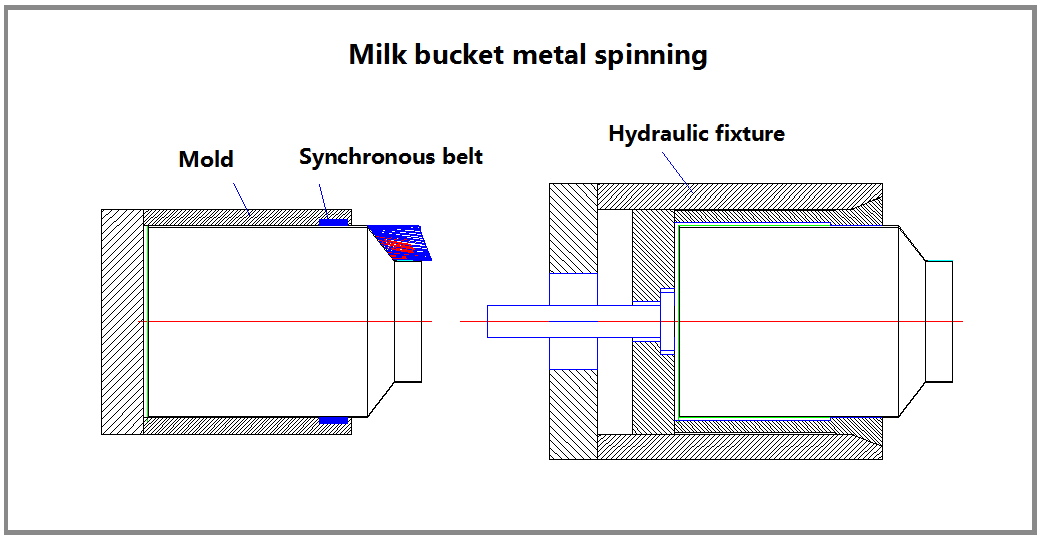

Milk bucket is commonly made by aluminum, aluminum sheet is made a cylinder shape by deep drawing in a hydroforming machine, deep drawing have high production efficiency than metal spinning, the size of diameter need to keep precision, otherwise it can not be putted in the spinning mold or fixtures.

The second step is to make the necking spinning in a spinning lathe, the key factor is to hold the workpiece tightly, otherwise the necking spinning will cause wrinkling.

If you make a simple mold, you can put a synchronous belt inside, this position need less gap to when put the workpiece, synonymous belt can prevent scratches and hold the workpiece tightly, if the gap is controlled within 0.5mm.

The better way is to desin a hydraulic fixture, it can open when you remove workpiece, it can clamp workpiece when it is spun. The following images explains the structure and principle of the fixture.

All the necking or tube spinning need a fixture, As long as the fixture can be tightened, spinning forming is much simpler.

5. Cylinder spinning

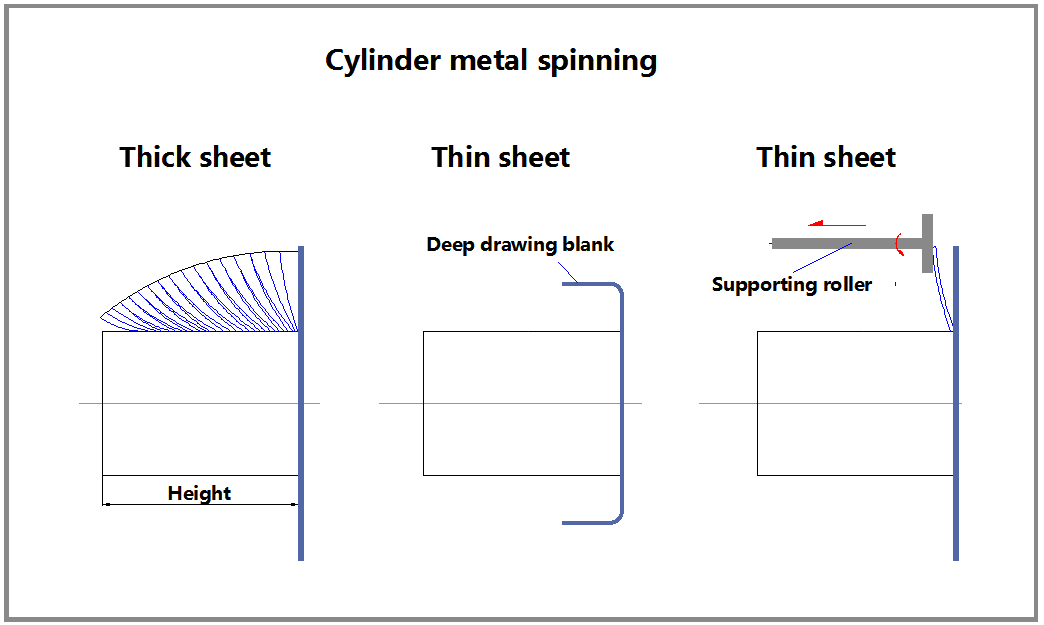

When the height value is less than 100mm, no matter the blank materials is aluminum, steel and stainless steel are easy to spin.

If the thickness of material is less than 1mm, the Max edge of work piece can be wrinkled in the spinning, Thin sheet metal spinning should choose the R6 roller if you spin it directly. In order to improve the strength of Max edge of work piece, there are two ways to improve it, at first, you can choose the deep drawing blank, second, you can use supporting roller to support the edge of work pieces.

If the thickness of material is more than 5mm, the interior material flows slowly, so heating can make the material slow smoothly, otherwise the Max edge of work piece will break.

When the height is over 200m, stainless steel spinning is hard to form as the ductility is not enough. The better way is to use the deep drawing blank to spin, it can make the higher height of cylinder.

6. Cone spinning

Cone are used in stainless funnel and home crafts, cone is a simple shape to make by shear spinning. You just need to control the right spindle speed, feed speed and gap to meet a smooth surface.

Recommended

- -Top twelve metal forming fabrication methods

2025-11-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27