Key Considerations for Purchasing a CNC metal spinning equipment

Key consideration for CNC metal spinning machine

Metal spinning is one of the metal forming processes. Many factory owners are considering investing in CNC metal spinning machines. There are numerous types and manufacturers of metal spinning machines available on the market. Choosing the right spin forming machine not only enables the achievement of product requirements, but also significantly enhances production capacity. This article focuses on presenting 10 crucial points to consider when purchasing a CNC spinning machine, in order to prevent you from making mistakes during the purchase process.

1. The types of CNC metal spinning machine

The CNC metal spinning machine can be classified into light-duty and heavy-duty types based on the difference in the spinning force. Light-duty can form the thin and soft metal sheet, it have high feed speed and spindle speed, so the production efficiency of light duty is higher. Heavy duty have stronger spinning force, it can spin thick and hard metal sheet.

The CNC metal spinning machine can be classified into double-roller and single-roller according to the number of spinning roller. the spinning force on the work piece is more balance by double roller, the spun product accuracy of double roller is higher. On the other hand, the final thickness of double roller is thinner than single roller.

What is CNC metal spinning machine >

2. How to choose a right CNC metal spinning machine >

You need to analyze the size, wall thickness, and precision of the spun products, then select the appropriate CNC spinning machine. the size of spun product is bigger, the specification of CNC metal spinning machine is selected, the wall thickness of spun product is thicker, it need to buy heavy duty spinning machine to output stronger spinning force, the precision of spun product is higher, you can choose the double roller CNC spinning machine.

3. The machine parameter you must to know

When you get a CNC metal spinning equipment quotation from manufacturer, they will offer you the equipment parameter, even though there is a little different from different factory, but we can check the key parameter from the specification or quotation.

● Motor power, lead screw and guide rail : these parameter decides the values of spinning force.

● Feed speed, spindle speed : these parameter decides the production efficiency

● The center height of spindle : Max blank diameter

● The distance between tailstock and headstocke : the height of metal spun product

4. The precision of CNC metal spinning machine

The precision is important for metal spinning forming, if the repositioning precision of machine is not good, it is hard to control the precision of metal spun product. the precision of CNC spinning machine is related to the casting bed heat treatment and CNC machining tolerance, the assembly accuracy of the guide rail, lead screw, spindle, hydraulic cylinder of tailstock.

We can’t see the process of machine manufacturing, but we can inspect the repeatability positioning accuracy of machine.

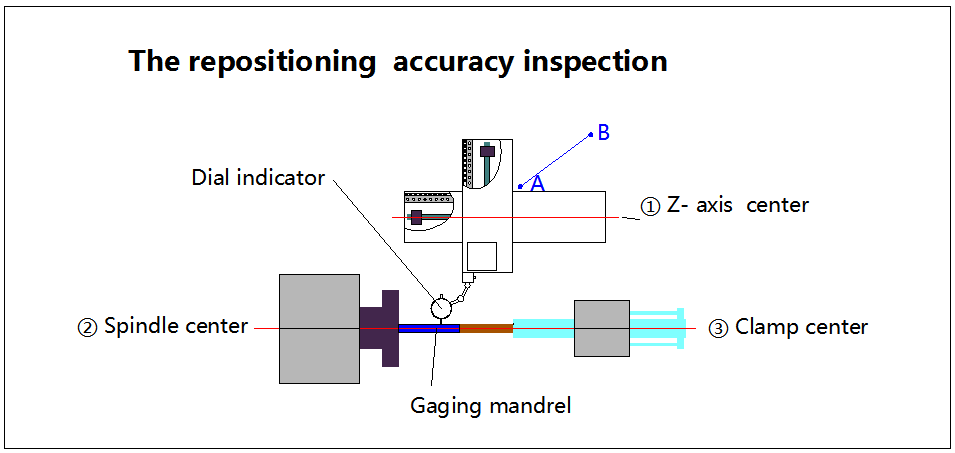

5. How to check the repositioning accuracy

You can put the the dial indicator on the tool mounting, the spindle stopping, First, operate the machine tool coordinate movement to point A and read the value of the dial indicator. Second, Move the machine from point A to point B and then back to point A from point B. You read the value of the dial indicator. If the value difference between the two stops of the machine at point A is greater than 0.01mm, it indicates that there is a problem with the machine's repeated positioning accuracy.

6. Precision misconception

Many people have a misconception that if the precision of a spinning machine can generally reach 0.02mm, then the products formed by spinning can reach 0.02mm. In fact, those who understand lathes confuse spinning forming with CNC turning. Compared with spinning, the parts processed by lathes are generally rigid parts, and the cutting will not cause metal spring back. However, the spun parts are thin-walled parts. Due to the metal spring back phenomenon during the cold extrusion process and the internal stress generated, the internal stress will cause the spun products to become elliptical.

Although the accuracy of metal spinning> is related to the precision of the CNC spinning machine, spinning force value, the performance of the metal raw materials, and the structural strength design, only we purchasing a CNC spinning machine with better precision, we can manufacture higher precision metal spun products. At the same time, The magnitude of the spinning force output by the machine can effectively overcome the spring back of the metal, thereby enhancing the precision of the spun products.

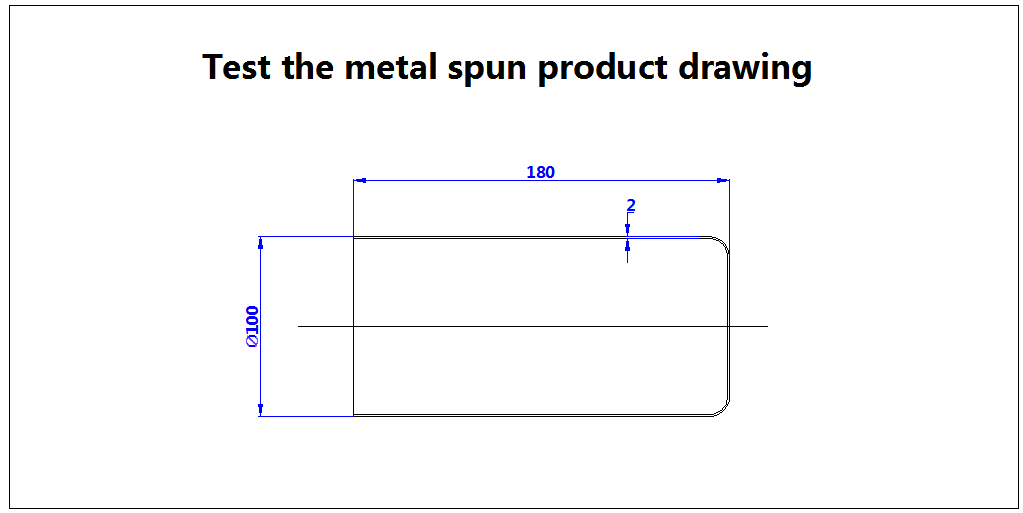

7. How to verify the performance of a CNC metal spinning machine

If want to test the accuracy and performance of the CNC metal spinning machine, you can use the following drawing to make a sample, you can use the stainless steel 304 thickness is 2mm, stainless steel is hard to spin than aluminum and steel, the ductility is worse and the springback is bigger, if the machine is not good, it will be break the work piece in the spinning forming. If the production accuracy is less than 0.3mm, you need to inspect the accuracy by go-no go gauge, it prove the accuracy and force of the CNC metal spinning equipment is good.

8. High precision requirements -Continuous production is stable

When you need to purchase a spinning machine to make high-precision parts. Many equipment salespeople tell you that they can meet the requirements. You'd better have the equipment company try to make samples according to your requirements at first, and then you can inspect the metal spun samples on site. Only if there are no problems in the continuous production of 100 pieces, you can purchase this equipment .

9. Metal spinning production efficiency

When you have a large quantity of production to purchase the spinning machine, Production efficiency> is the primary consideration, spindle speed and feed speed determine the production time of a single spun product. Spindle speed and feed speed are faster, the production efficiency is higher. Usually, high-efficiency spinning machines cannot produce thick materials. This is the difference between a light -duty spinning machine and a heavy-duty spinning machine. A heavy spinning machine is similar to a heavy truck, while a light spinning machine is similar to a small sports car.

10. Which CNC metal spinning machine is good

There are many CNC spinning equipment manufacturers in the United States, Europe, Japan and China. Different manufacturers have different advantages in different spinning fields.The spinning machines are made by Europe, the United States and Japan are indeed very good, but their machines are not cheap. Machines from China is cheaper.

You can read this article -metal spinning report > , it induces excellent CNC metal spinning machine manufacturer in the world.

Recommended

- -Top twelve metal forming fabrication methods

2025-11-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27