7 Important spin forming tips for Beginners

Spinning forming technology

Spin forming is a fascinating and challenging job. For those who have no experience with spinning, it might be like CNC turning. However, once you delve deeper into it, you will find that it takes many years of accumulation to master the spinning technique well. If you haven't yet entered the spinning industry or have been engaged in it for a short time, please read this article patiently. After reading it, you will be able to have a systematic understanding of the general situation of the spinning industry.

1. The fundamentals of spin forming technology

The basic techniques of spin forming mainly include mandrel design>, installation of mandrel and roller, tool and parameter setting, tool path drawing and numerical control programming. Except for mold design and tool path drawing, the other matters are all simple operation techniques. As long as you operate them 3 to 5 times, you will basically master them. Mold design and tool path require analysis and comparison of different products and accumulation of experience. Technical skills can be greatly enhanced.

2. How long to learn metal spinning technology

After successfully debugging 20 different types of spinning products within one year, simple aluminum spinning and iron spinning products can basically be formed. However, stainless steel has relatively poor ductility and high tensile strength. Compared with aluminum and iron, it is more difficult to form. Besides having a good drawing of metal spinning tool path, it also has high requirements for the performance of the spinning equipment. Generally, it takes about three years to reach a good level.

3. Factors affecting spin forming

The spinning technology is not only about drawing the tool path and programming. In fact, there are many factors influencing spinning forming, which we can summarize into the following five points

① Tool path and CNC programming

These are the most important for spin forming, tool path drawing needs experience, For beginners, many people do not know how much each roller should go, what the forming R value should be selected, what the feed rate should be chosen, or what the spindle speed should be selected. Here is a document showing the tool path diagrams for spinning different metals, which can be provided for free for everyone to download and study.

② The performance of spinning machine

The influence of machines on spin forming mainly lies in two aspects. First, the magnitude of the spinning force output by the machine. If the force of the spinning machine is insufficient, when spinning hard and thick metals, the insufficient spinning force cannot overcome the springback of the material, resulting in the workpiece not being able to hold on the mold closely. Secondly, the repeatability accuracy of the spinning machine is insufficient. When spinning thin material sheets, occasional cracking may occur during the same production process. This is because the gap between the roller and the mandrel is sometimes loose and sometimes tight. Both overly tight and overly loose gaps can easily lead to cracking.

③ Mold and roller installation

The runout of the mold and the roller can cause unstable clearance between them. Therefore, the runout of the mold should be controlled within 0.05mm and that of the roller within 0.02mm.

④ Material selection

After meeting the customer's requirements, metals with good formability should be selected as much as possible. The good spinning performance mainly depends on three factors of the material: low hardness, low tensile strength and high elongation.

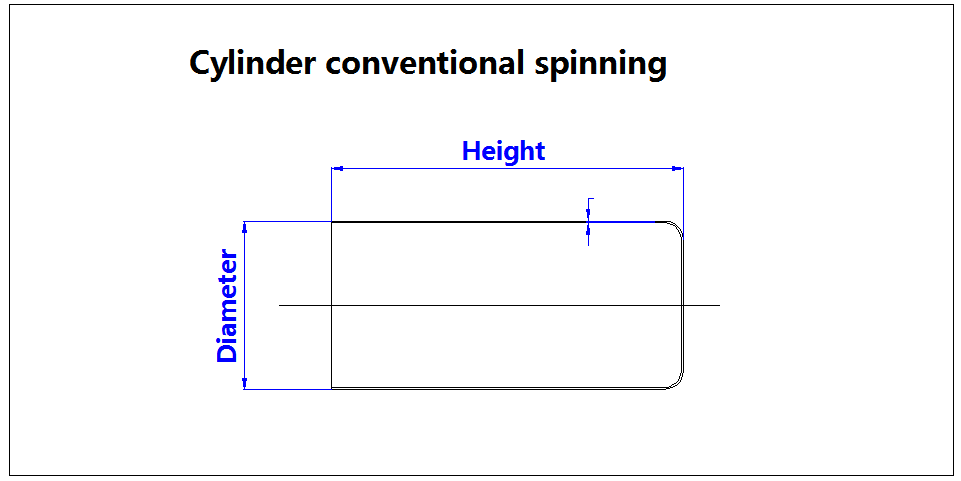

4. How to determine a spun product is difficult

During the forming process, the ductility of any material has a certain upper limit. When the material is stretched to a certain extent and exceeds its own ductility rate, the workpiece will break. For spinning, the shear spinning of cone is the simplest. The cylinder conventional spinning is hardest, you can check the ratio = diameter / height, if the ratio value is less, it is hard to spin.

Generally, both aluminium and iron have good ductility and can be made to a height of over 600mm as long as the machine's stroke is sufficient. But when the cylinder height of stainless steel spinning is over 200mm, it is hard to spin.

5. Is spinning forming fast

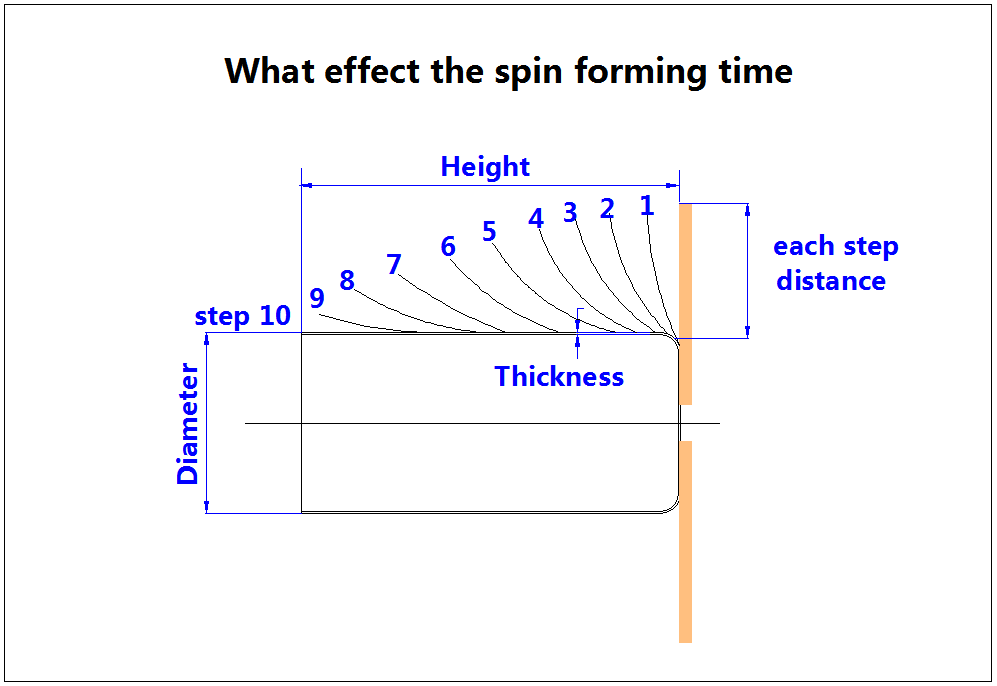

The fastest processing time for a product through spinn forming is 20 seconds. Most of products are expected to take 2 to 5 minutes, while large products may require more than 10 to 20 minutes.

The time of spinning forming is the key to the efficiency of spinning production. The time of spinning forming is mainly related to several factors. First, the larger the product diameter, each step distance of the roller moves, and the more time is required. Second, the spun metal product is higher, the more steps are required and the longer time to spin. Third, the thicker the thickness, the lower the spinning feed will be and the longer the forming time will be.

How to improve the production efficiency >

6. Is the cost of metal spinning expensive

Metal spinning is more suitable for making medium and small batch or large thin-walled rotary parts. Spinning dies only require individual mandrel, and the production cost is low. Although the processing speed of spinning is a little slower than that of hydroforming, spinning can complete the forming, trimming, and rolling processes on one machine, while hydroforming requires several processes and additional molds to complete the trimming and rolling processes. Therefore, the mold installation and machine adjustment for spinning are much lower in cost than those for hydroforming. It has obvious advantages in medium and small batch production.

In addition, spinning has obvious advantages in the forming of thick metals and large metals. This is because the force used in the spin forming is 1/3 to 1/5 of that of hydroforming. To form products of the same size, hydroforming requires the manufacture of larger machines to withstand the forming force, so the hydroforming machine cost is much higher in large-scale processing.

7. Why stainless steel is hard to spin

When you have mastered the aluminum spinning and steel spinning, the same shape may not be formed by stainless steel. This is because stainless steel has poor ductility and high tensile strength, and it is prone to springback during the forming process. If the drawn spinning tool path cannot make the workpiece adhere to the mold, stainless steel is very likely to be thined and even broken by the roller pulling during the forming process. Therefore, spinning stainless steel not only requires good spinning technology, but also a spinning machine with high precision and large spinning force. If you use a light-duty spinning machine to form stainless steel, it is very difficult to form and control the precision.

Recommended

- -Spin forming principle-CNC metal spinning technology

2026-02-22 - -What is CNC metal spinning machine tool

2024-08-15 - -Aerospace components-Precision manufacturing of CNC spinning

2025-01-29 - -Metal spun products - what product spin forming can do

2025-01-24 - -How to design a CNC metal spinning mold | mandrel

2024-04-12 - -Metal spinning materials

2024-04-14 - -Metal spinning development and prospect

2024-10-31 - -How to choose a CNC metal spinning machine

2024-04-18 - -Metal spinning process and technology

2024-11-30 - -How to control the accuracy of CNC metal spinning

2024-07-27